11 Tips to Safely Extract Stuck Tractors and Farm Equipment from Mud

Weather changes year-round, and situations like rain, snow, and ice can complicate a day’s work in the field. Fields become very muddy when snow melts away or harsh rain comes failing down. Therefore, these conditions get your tractor stuck. Extracting your stuck tractors or farm machinery takes time, and time is already precious when you’re making field preparations for spring planting.

With time being a precious commodity on the farm, it’s best to stay prepared and maintain safe practices when extracting stuck tractors or other achinery. Read our top 11 tips for recovering your stuck tractor.

1. Be Equipped with the Right Recovery Tools

Use recovery straps designed to recover a vehicle from any sticky situation. You want the pulling equipment rated 1 or 1.5 times the weight of the stuck machinery. With that in mind, we carry recovery straps with break strengths from 20,000 – 400,000 lbs, variations from 1- to 4-ply design so you get the width you want with the strength you need, and CODURA at the eyes of the strap to resist wear and tear.

If you need help in deciding which of our heavy-duty tiedown straps is right for you, need a custom length, or would like to purchase in large volumes, call us at 800-969-6543!

The terms recovery straps and tow straps are used interchangeably, but it’s important to note that both cannot be used for all the same purposes. Read our guide to vehicle tiedown straps to learn the differences.

2. Use a Formula to Calculate Required Minimum Recovery Capacity

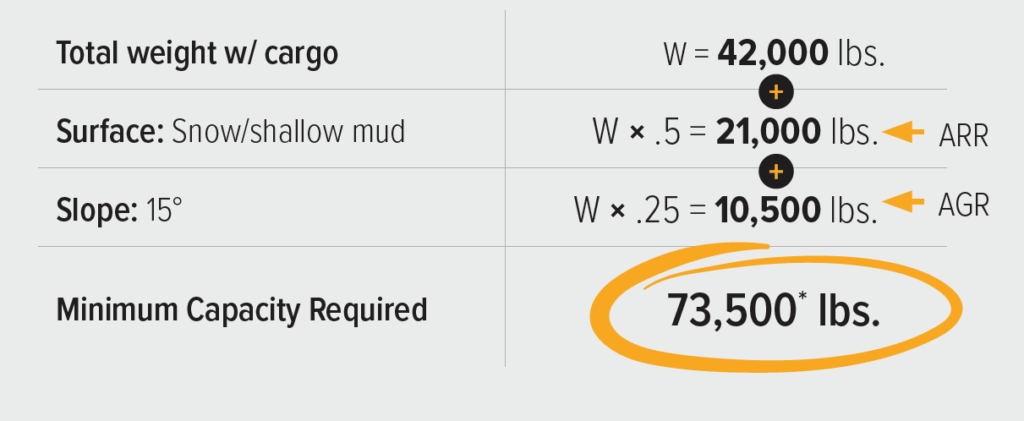

To effectively extract a stuck tractor in the mud, sand, gravel, snow, etc., you’ll need to do some quick simple calculations. From our blog on Extracting a Stuck Vehicle, there is a formula to calculate the required minimum recovery capacity:

Minimum Required Capacity = W + ARR + AGR

(W = total vehicle weight, ARR = additional rolling resistance, AGR = additional gradient resistance)

Find the Total Vehicle Weight of Your Tractor or Farming Equipment.

Know the size of the stuck equipment in order to pull its weight. Unload anything inside the stuck vehicle as this might help the extraction process. The lighter the stuck vehicle is, the easier it may be to move and less force it will have against your towing vehicle.

Finding Additional Rolling Resistance (ARR)

Part of using the formula that comes in handy to how deep the machinery is calculating the additional rolling resistance (ARR). You need more towing power and recovery equipment with high load ratings when the tires get buried deep into the surface or drag on the ground

ARR equals the surface in which the vehicle is stuck or will need to get over in order to become free. Different surface types have different multipliers that, when multiplied by total vehicle weight, give you the ARR. Below gives multipliers for different surface types:

Calculating gradient resistance (AGR)

Gradient resistance (AGR) is the degree of slope that the extraction may take place on. The greater the slope, the higher the multiplier. Just take the total weight of stuck vehicle and multiply by appropriate multiplier. Read below the table of multipliers for different degrees of slope:

| 15° Slope | (W x .25) |

| 20° Slope | (W x .33) |

| 30° Slope | (W x .5) |

| 45° Slope | (W x .75) |

Read the image below an example of how to apply the equation:

3. Get Towing Vehicle Close as Possible to the Stuck Tractor or Equipment

The shorter the attachment between the towing vehicle and stuck equipment, the less chance it’ll cause injury if there are flying debris. When the connection is short, debris is likely to hit the tailgate than the windshield.

However, make sure the attachments are long enough so the towing vehicle stays on solid ground. Having at least 25 feet of cable, rope, strap, or chain will allow some flexibility.

4. Try to Only Make Two Attachment Points

The two attachment points are to the towing vehicle and stuck vehicle. Don’t make knots to the recovery straps, as the strap is at its full strength when flat. Tying the straps together reduces the overall power and defeats the purpose of what it can do.

5. Keep the Tailpipe Uncovered

Exhaust gases build up inside the stuck vehicle, so inspect the tailpipe of the stuck vehicle by making sure the exhaust gases ventilate nd not stuck in the mud or obstructed. If stuck in the mud, dig around the tailpipe.

6. Raise or Consider Disconnecting the Trailer or Attached Implements

If the wheels of your tractor start to spin, try raising the implement and engage the differential lock if the tractor has one. Then, assess the muddy area and determine whether or not you try and make it through without getting stuck. If you do go through, keep the implement raised and don’t stop while proceeding.

If you need to remove the trailer or implement, consider separating the load from the stuck vehicle to help with the extraction (if done safely). Disconnecting trailers should be a last resort as it can lead to other troubles, such as being damaged or harder to reach.

7. Dig Mud Away and Place Boards Behind Tractor

If the tip above doesn’t work, digging mud away from your wheels may help with the extraction process. Shovel dirt from the front and back of wheels, and place boards behind the tractor in line with the wheels. Boards can provide traction needed to back out slowly of the mud.

8. Pull in a Straight Line when Possible

The best way to pull is to pull forward and straight. It also helps to pull the stuck vehicle backwards, depending on the situation. For example, if your vehicle ran off into a muddy area, it would be easier to pull it backwards than go through the field.

9. Make Sure Towing Vehicle Has Traction

Don’t get the vehicle stuck in the mud or other sticky situation. This defeats the purpose of extracting the stuck vehicle. Good traction will help the stuck vehicle to come out.

10. Inspect Equipment and Recovery Tools

This is NOT an accurate representation of recovery straps to extract a tractor. This is to show how to inspect a tiedown and other accessories and how to neatly put together.

Check your equipment that you pulled out after the extraction. The deeper the tractor was in the mud, the more important the inspection is. A few parts to check would be the spinner or guard, hoses, fittings, wagon, lights, brake lines, fuel tanks, and exhaust systems.

Also, inspect your recovery tools for any breaks, damages, or defects. Do not use tiedowns if you notice burns, have tears or holes, broken stitching, or abraded. If the chain, clevis, or hook has stress cracks or other signs of damage, they are not good to use again.

Dry and clean tiedowns before storing away to avoid mold or mildew, and store any other recovery tools in a safe place. If you leave them out, you risk them deteriorating if they get rained on and under harsh conditions of sunlight. If the tools are still in good operating condition, this will come in handy the next time you’re in a sticky situation.

11. If Unsure of Performing Extraction, Don’t Sweat and Call a Professional

If you assessed how badly the equipment is stuck and believe further damage may result if you continue, call a professional. It’s better to be safe and avoid any injury, and have some help to recover your equipment.

NOTE: this article contains safety information about the use of synthetic web slings. However it does not contain all the information you need to know about handling, lifting, and manipulating materials and loads safely. Sling use is only one part of a lifting system and it’s your responsibility to consider all risk factors prior to using any rigging device or product. Failure to do so may result in severe injury or death due to sling failure and/or loss of load.

At US Cargo Control, we believe you deserve the highest quality products to get the job done. If you would have any questions about our towing & auto hauling accessories, give our team a call at 800-969-6543 or email us at customerservice@uscargocontrol.com.