Extracting a Stuck Vehicle

How to Calculate Minimum Winching Effort & Minimum Working Load Limit

When extracting a stuck vehicle, many factors can affect the actual pulling force needed, as well as selecting recovery equipment with high enough load ratings.

During a recent Iowa Corn Growers Event hosted at US Cargo Control headquarters, Tim Sanders, a Trucking and Transporation expert, and USCC business development specialist, gave an informative overview of what goes into effectively extracting a vehicle stuck in the mud, sand, gravel, snow, etc.

When work needs done, it seems tempting to just grab a strap or chain and pull until something happens. However, if you take a few minutes to do some simple calculations, you'll likely save time in the long run and more importantly, help ensure the safety of those around the extraction scene.

Calculating the Required Minimum Recovery Capacity

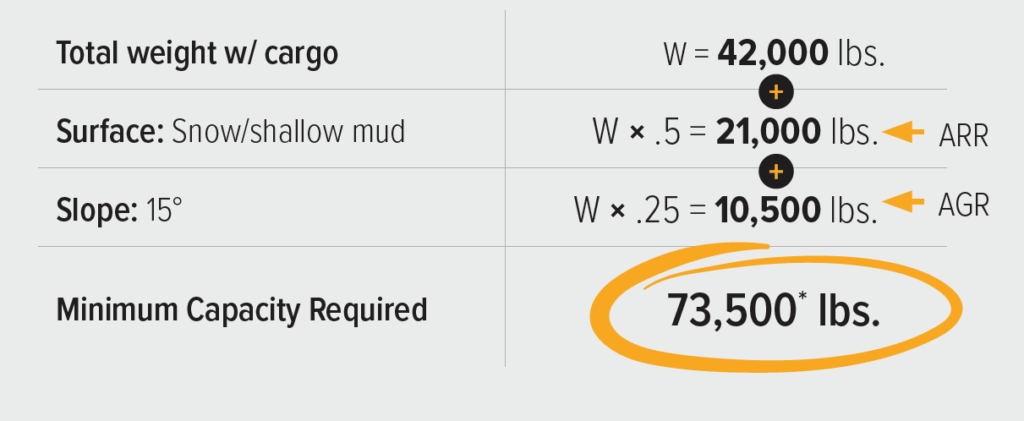

Total vehicle weight (W), additional rolling resistance (ARR), and additional gradient resistance (AGR). Once you have these calculations, you can quickly determine the recovery equipment strength you will need:

-

What does the stuck vehicle weight, including all cargo, attachments, trailers, etc.?

This is the "W" part of the formula. -

What factors will add to the pulling effort and safe working load limits required to pull the total weight of the vehicle?

When we say "additional factors" we're mainly talking about two things: additional rolling resistance (ARR) and additional gradient resistance (AGR)

Minimum Capacity Required = W + ARR + AGR

Calculating Additional Rolling Resistance

Additional rolling resistance (ARR) is essentially the surface in which the vehicle is stuck or will need to get over in order to become free. Different surface types have different multipliers that, when multiplied by the total vehicle weight, give you the "ARR."

Keep in mind that these calculations assume the wheels are level with each other.

Calculating Gradient Resistance

Gradient resistance (AGR) is simply the degree of slope that the extraction may take place on. The greater the slope, the higher the multiplier. Again, you will take the total weight of the stuck vehicle and multiply by the appropriate multiplier.

Example Calculation

Let's say the total weight of the stuck vehicle is 42,000 lbs., and it's stuck in the snow with a 15-degree slope. Can you figure out the minimum capacity required? Remember the formula is:

Minimum Capacity Required = W + ARR + AGR

See below for the answer.

Selecting the Right Recovery Straps

Make sure the working load limit of the recovery equipment is greater than the minimum capacity required. Additional resistance could be encountered when the stuck vehicle is deeply submerged, or there is damage to the vehicle that prevents it from moving. When in doubt contact a vehicle recovery expert.

More Vehicle Recovery Resources

If you're needing to pull an automobile out of snow that's close to a public roadway, there are specific steps to take to ensure safety beyond just recovery capacity. Click the link above to learn what they are.

We also have resources that cover the common questions our team gets like how to choose a recovery strap and auto-recovery straps vs. tow straps.

NOTE: This article contains important safety information about the use of synthetic web slings. However, it does not contain all the information you need to know about handling, lifting, and manipulating materials and loads safely. Sling use is only one part of a lifting system and it is your responsibility to consider all risk factors prior to using any rigging device or product. Failure to do this may result in severe injury or death due to sling failure and/or loss of load