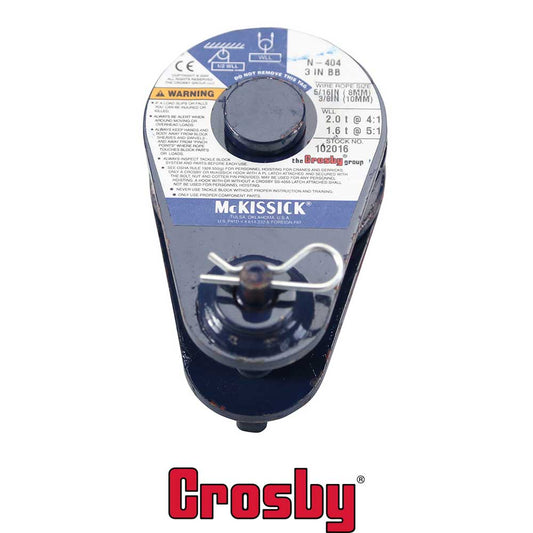

Crosby® McKissick® Snatch Blocks

The Crosby® Group LLC has become a leading source for accessories used in the lifting and material handling industry. McKissick®, part of Crosby® since 1959, is one of the world’s largest producers of blocks.

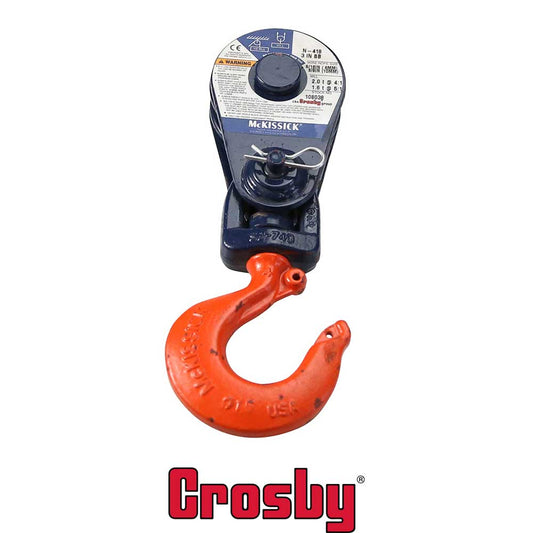

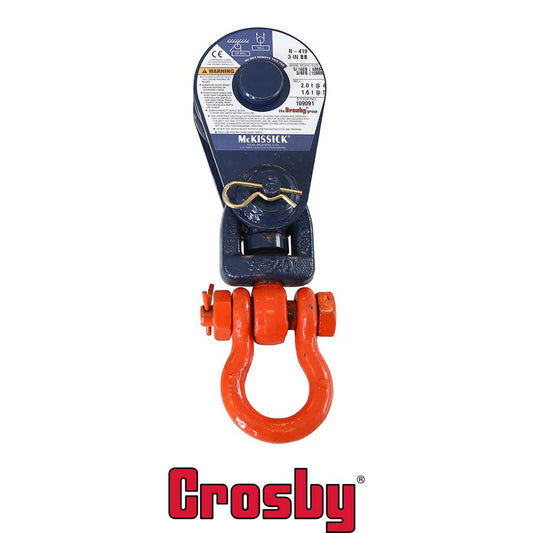

We sell a wide range of McKissick® snatch blocks — including both hook and shackle assemblies, as well as tailboards — to help ensure you find the appropriate block for your specific application. Crosby® also provides detailed application and warning information attached to each all-steel block to assist you in the proper selection.

Depending on end fitting connection, Crosby® McKissick® blocks have forged alloy heat-treated hooks and forged steel swivel tees, yokes, and shackles. End fittings are also Quenched & Tempered®, Crosby®’s perfected heat-treatment method to reduce the risk of brittle, catastrophic failure. Hooks and shackles on 4-1/2” through 14” sizes can easily be interchanged without disassembling the block. The hook style can be furnished with an S-4320 hook latch, sold separately.

The opening feature permits insertion of a rope while the block is suspended from a gin-pole, a three-legged lifting device used to raise loads like for placing antennas. On 418 and 419 blocks sizes 3” through 18”, a bolt-retaining spring assures no lost bolts, while 3” to 10” offer dual-rated Wireline sheaves. McKissick® blocks have pressure lube fittings for sheaves.

Crosby® snatch blocks are Fatigue Rated®, as they’re designed to meet specific fatigue performance levels. They meet the requirements for Euronorm standards: 20,000 cycles at 1-1/2 times the working load limit. Ultimate load — the average load or force at which the snatch block fails or no longer supports the load — is 4 times the working load limit.

Blocks come from the factory equipped with RFID chips, which you can program and utilize in your inspection efforts. All Crosby® blocks are identified by type, size of block, size of Wireline to be used, working load limit (in both metric and short tons), and the manufacturer’s name boldly marked on the product.

The theoretical reserve capability of a snatch block should be at least 4 to 1. McKissick® blocks are dual-rated. They are metric-rated to a design factor of 4 to 1 and, with a world-class design, are applicable to worldwide use without conversion. Their U.S. rating — compared to other blocks rated in short tons — is 4.5 to 1.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these blocks meet other critical performance requirements, including fatigue life and material traceability, not addressed by ASME B30.26.

For oilfield use, Crosby®’s McKissick® manufacturing plant is American Petroleum Institute (API) Q1 certified. McKissick® is also certified to ISO 9001 standards by Det Norske Veritas (DNV).