Toll Free: 866-444-9990

Español: 844-871-5153

Local: 319-213-9180

Hours: M-F, 7am - 5pm CST

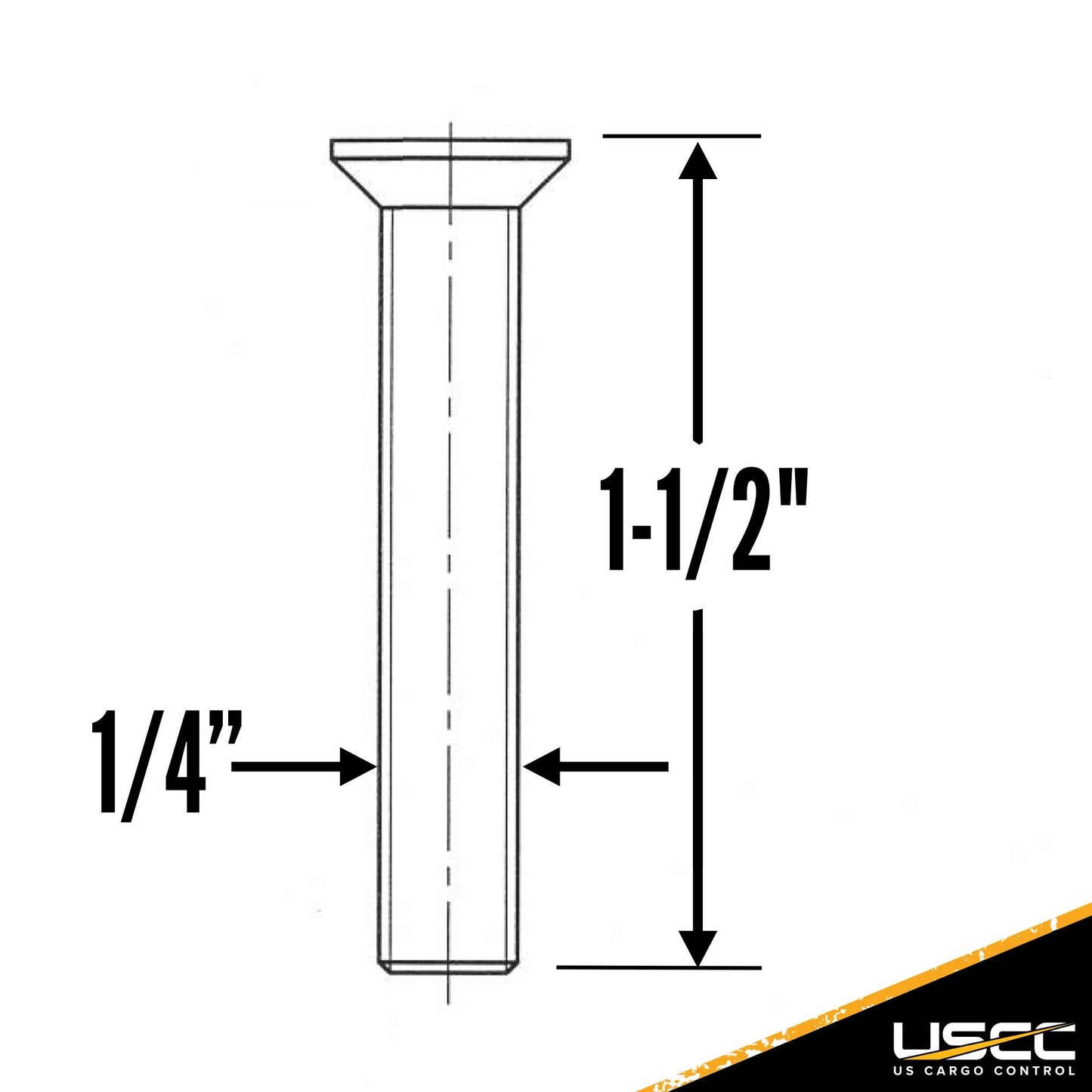

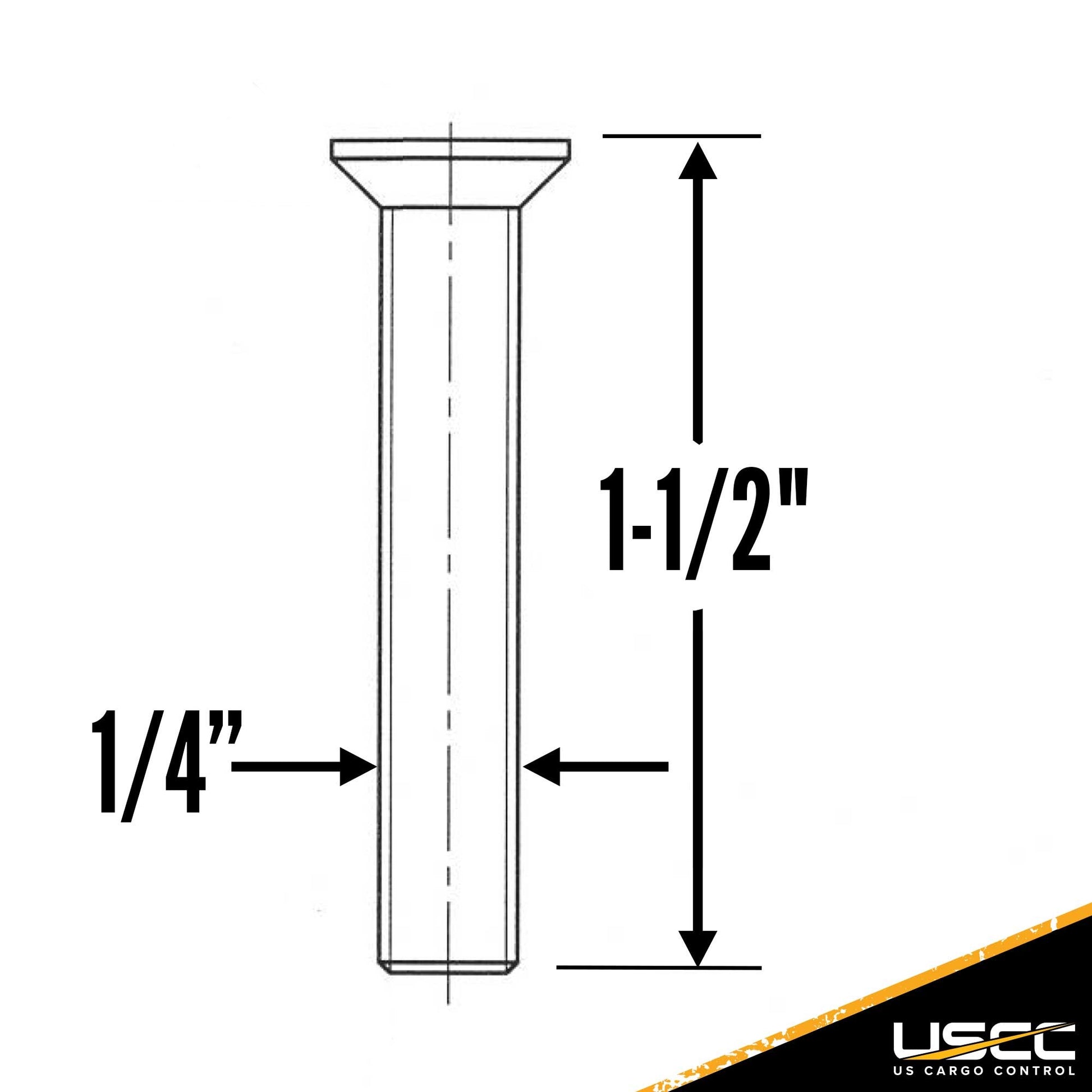

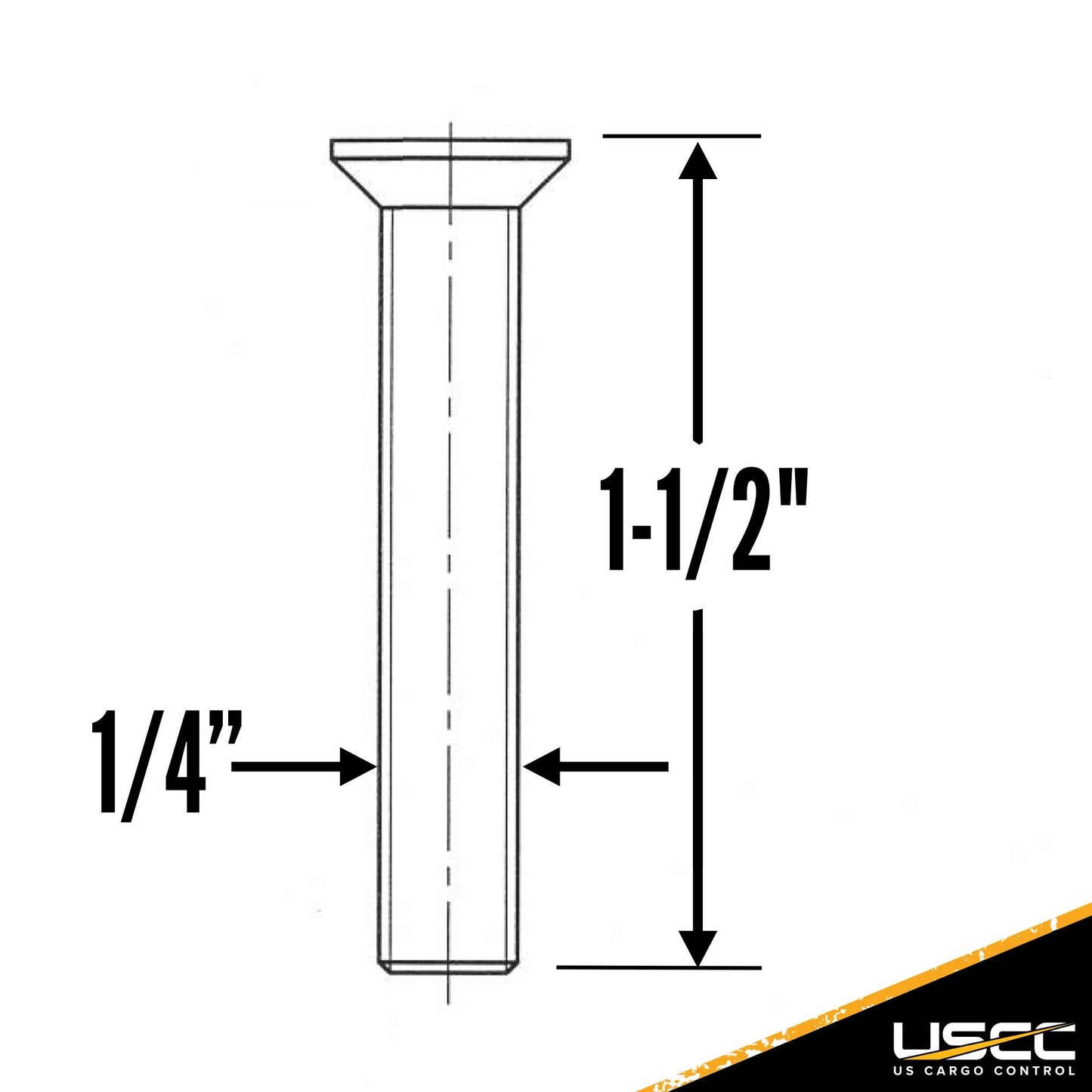

This fastener pack for L-Track is designed to quickly secure your L-Track tie-down rails. Measuring 1-1/2" in length, these stainless-steel bolts will suit most airline track installations and stand up well to the elements. The pack includes 10 sets of bolt/nut/washer.

For more information on how to install L-track, and video demonstrations, see our How to Use and Install L-Track and L-Track Systems page.

Looking for more L-Track Accessories? Check out our full lineup on our L-Track Fittings and Accessories and L-Track Straps pages to grab the gear you need to round out your L-Track system.

California Residents: WARNING

In order to achieve maximum design load capacity, the taper of the machine screw head must match the countersink angle of the track hole, i.e., full surface area contact between the fastener and track.

The countersink angle of the track hole is 120 deg, both per the manufacturer's spec on the item page and from my validation measurements. This necessitates a head taper of 120 deg. Unfortunately, a 120 deg tapered machine screw does not exist.

The spec US Cargo Control fasteners listed here claim to have a head taper of 90 deg, not 120 deg (which again, doesn't actually exist). Not only that, but a 90 degree head taper is the standard taper for metric, while the standard for imperial is 82 deg. This leads me to believe these fasteners have an actual taper of 82 deg because 1/4-20 90 deg taper machine screws also don't exist. Specialty fasteners with a 100 deg taper are available in imperial sizing, but usually in limited lengths.

So, in conclusion, first you cannot achieve the max design load for this USCC L-Track because a 120 deg tapered machine screw doesn't exist. Second, if you want to achieve the highest possible load rating, understanding that a 120 deg machine screw doesn't exist, and these are likely 82 deg tapered, go to McMaster Carr and purchase some 1/4-20 100 deg tapered machine screws to your preferred length.

D.C.

Thank you so much for taking the time to provide a review on this product! We are sorry to hear about the degree and load design issues you saw with our L Track and Fastener Pack. This information has been sent over to our quality team so we can review this moving forward. We appreciate your feedback and your expertise as it helps us to continuously evaluate our products! If you wish to discuss this further or have any questions, you can contact us by emailing customerservice@uscargocontrol.com or by calling 866-444-9990. We are open Monday-Friday 7am-5pm CST.

Hardware was as advertised but not what I needed. The L track has a 100deg countersink while these bolts are 90deg. I don’t understand they sell hardware that doesn’t match the L Track.

Thank you for taking the time to provide us with a review on this product. We are happy to help you find the right hardware for your product. Please call our sales team at 866-444-9990 opt 1 and one of our product experts can help find the right hardware for your application.

Didn't realize the 72" rails have 15 holes per side as only purchased one package of nuts and bolts which included flat washers only. Luckily my local Ace hardware had the exact same ss bolts and lock washers which I used when installing.