Eye Bolts

Rigging & Lifting Eye Bolts

Eye bolts are an essential component for many in the lifting and rigging industries - most commonly to add an additional attachment point or anchor to your setup. Compatible with wire rope / cable, hooks, and many other rigging staples, they offer practical solutions for improved versatility and safety in a variety of applications.

If you have any questions about which will work best for your specific needs, contact our sales team and we will be happy to assist you.

Types of Eye Bolts

Selecting the right bolt for the job is essential for worksite safety, project reliability, and more in your lifting and anchoring operations.

For example, standard eye bolts without a shoulder are designed for vertical techniques only.

Forged Eye Bolts

Forged eye bolts - available in both galvanized and stainless steel - are commonly chosen for heavy-duty and critical applications like industrial lifting and construction. Forged steel is harder, stronger, and more durable than machine parts or cast forms, due to the construction process.

Shoulder Eye Bolts

For angular lifting and loading, a shoulder eye bolt should be used. The reinforced shoulder helps maintain the strength of the eye and prevents the shank from bending or deforming when used at an angle. This makes it perfect for rigging applications.

Note: It's important to remember that loading at an angle will significantly reduce the rated capacity. Generally, a 75 degree angle reduces the working load limit by 45%; a 60 degree angle reduces it by 65%; a 45 degree angle reduces it by 75%. Never load at an angle less than 45 degrees from the bolt center line, and always verify angular working load limits with the manufacturer before use.

Available in both galvanized and stainless steel.

Machinery Eye Bolts

Used as a connection point in rigging applications, machine eye bolts feature a fully threaded shank and are used to connect to machinery and other equipment. This makes them a great connection point for hoists, slings, and other lifting equipment.

Galvanized Eye Bolts

Made with a thin coating of zinc oxide, the steel is protected from elements that lead to corrosion and oxidation. It's well-suited to most applications where exposure to moisture could be a concern, although it offers less corrosion-resistance than stainless steel.

Galvanized is also a great value as it tends to be less expensive but still maintains its strength and durability.

Stainless Steel Eye Bolts

Stainless steel eye bolts offer a higher level of corrosion-resistance when compared to galvanized, making them the preferred choice for marine, outdoor, and chemical applications.

Why Does Stainless Steel Offer Better Protection?

It's made from an alloy of chromium and low carbon steel. This combination offers inherent anti-corrosion properties, meaning stainless steel eye bolts will retain their resistance to corrosion even if the stainless steel becomes scratched.

The two different grades of stainless steel we offer are type 304 and type 316. 304 resists most oxidizing acids and can withstand ordinary rusting, making it a good choice for outdoor uses in agricultural, automotive and construction environments.

316 is considered marine grade because contains molybdenum, which makes it resistant to ocean water mist or spray, so it's especially useful in extreme moisture conditions or in a high chloride environment.

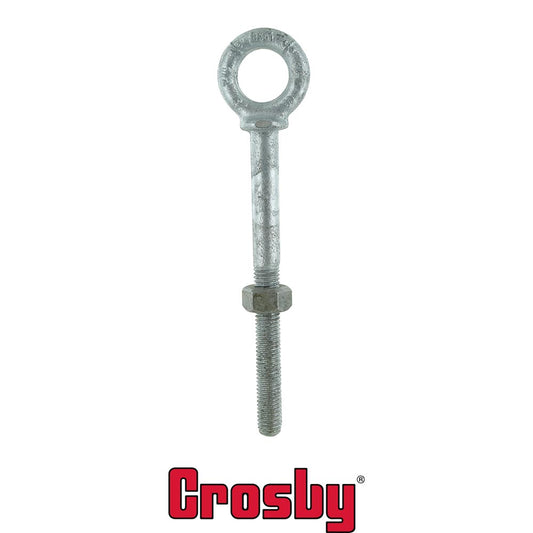

Crosby® Eye Bolts

Crosby® is a trusted manufacturer whose USA-made products are a favorite of many in the industry. Crosby eye bolts include shoulder, machine, eye nuts, and pad eyes.

Eye Fabrication

There are several eye styles available for eye bolts, including turned, welded and forged.

Forged eyes are the strongest option. Forging means the metal is hammered or pressed into form. When the steel takes shape, its grain structure stretches and aligns, which creates a stronger piece of finished metal.

Turned eyes are created by bending the metal to create the eye, leaving a gap in the circle. Turned eye bolts are only suited for lightweight, low cost applications - not for lifting or rigging.

Stainless steel welded eye bolts are similar to a turned eye, except the eye has been welded together to create an unbroken circle. This increases the working load limit, making it suitable for more intense applications.

How to Choose The Right Eye Bolt

- Determine the Required Working Load Limit: Make sure your choice is rated for your intended load capacity.

- Factor in the Environment: Use stainless steel for marine or humid conditions, or galvanized for general rust resistance.

- Match Your Rigging Equipment: Ensure compatibility with hooks, shackles, and slings.

Industry Compliance

Our eye bolt anchors are clearly noted with the standards they are compliant with. Most meet or exceed ASTM F541 & ASME B18.15 requirements, and all of our Crosby options are also compliant with ASME B30.26.

Safety & Usage Guidelines

There are several guidelines to remember when using an eye bolt for rigging, anchoring, pulling, pushing, or hoisting:

- Regular rigging eye bolts should be used for straight line pulls only. For angular lifts, shoulder eye bolts are required. Without the shoulder to reinforce the bolt, it can bend or break from the angled pull.

- Always inspect a threaded eye bolt prior to use and make sure the threads and receiving holes are clean.

- Remove from service if the shank or eye has been bent, elongated, or deformed.

- The threaded part must protrude through the load so the nut is allowed full engagement of threading. If it protrudes too far through the load, you may need to shim the bolt with washers between the nut and the load prior to putting the nut on.

- Store in a dry area to prevent rust and degradation.

Other Eye Bolt Options

US Cargo Control offers some less common eye bolt anchors that are designed with stainless steel eyes (nuts and washers included where indicated).

- U-Bolt - Shaped with a curved base, two threaded arms offer fastening points for a secure fit. This stainless steel U-bolt is ideal for attaching pipes, rods, cords or wiring to a machine, pole, beam, etc. Depending on the situation, a cross piece insert can make it more secure.

- Eye Bolt with Ring - This stainless steel hardware is designed to receive rigging products such as a wire rope or shackle. Includes a nut and washer.

- Lag Screw Eye Bolts - Stainless lag eye bolts are threaded to work with wood - they have a tapered, sharp end. An excellent anchor point with a longer length for a variety of exterior and interior uses. These wood eye bolts do not have a working load limit, since their abilities are dependent on the quality of your wood and the overall installation.

- Lag Screw with Ring - Tie down eye bolts such as one with a lag screw design are commonly used in the rigging industry to anchor wire rope. Like the standard lag screw, the lag screw with ring is used as a point of attachment in wood.

- Ring Nail - Used as an attachment point in wood, it has ridges in the shaft to hold it in place. Stainless eye bolts are made from type 304 steel for excellent protection against weather conditions and corrosion.

- Eye Rivet - Designed with a smooth shaft to fit into a pre-drilled hole, the rivet end is impacted once installed. This makes it wider, creating a permanent fastener. Great for applications where lightweight and high strength anchors are important.

Questions?

Choosing the right eye bolt for the job is important. If you need help in selecting the best option or in finding other rigging supplies like shackles, turnbuckles, and more, contact our of our product experts.