Toll Free: 866-444-9990

Español: 844-871-5153

Local: 319-213-9180

Hours: M-F, 7am - 5pm CST

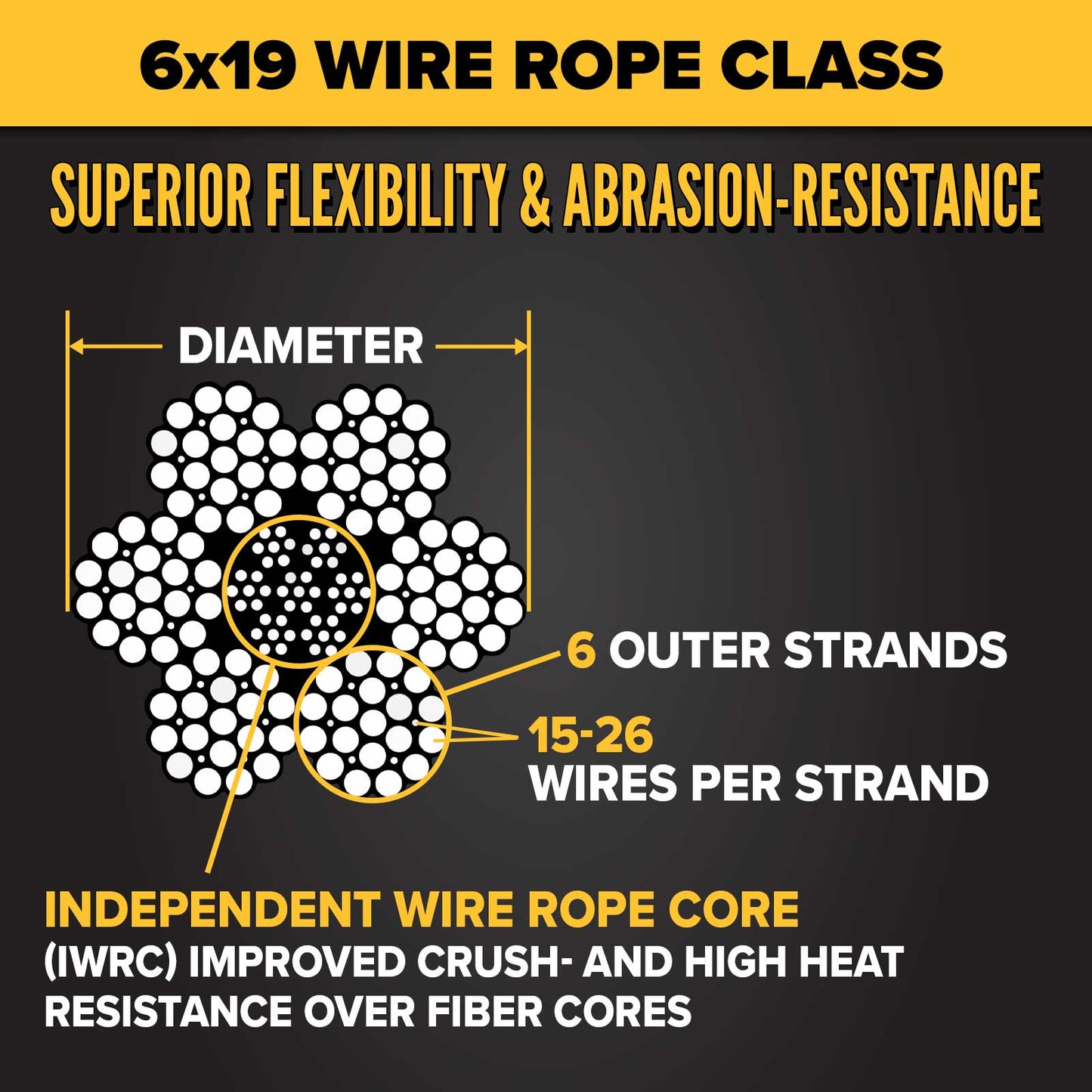

Made of strong Extra Improved Plowed grade steel (EIPS), this galvanized wire rope belongs to the 6x19 class, which is known for flexibility and abrasion-resistance. Along with the 6x37 class, 6x19 wire rope is the perfect general use steel cable and can be used for many applications, including as hoisting rope, suspension cables, winch lines, and more.

The 6x19 configuration offers better abrasion-resistance than the 6x37; however, it is less flexible and fatigue-resistant.

Our wire rope is made using EIPS-grade cable. EIPS (Extra Improved Plow Steel) refers to the strength of the wire rope - its tensile strength is around 10% greater than an IPS grade, improving the break strength.

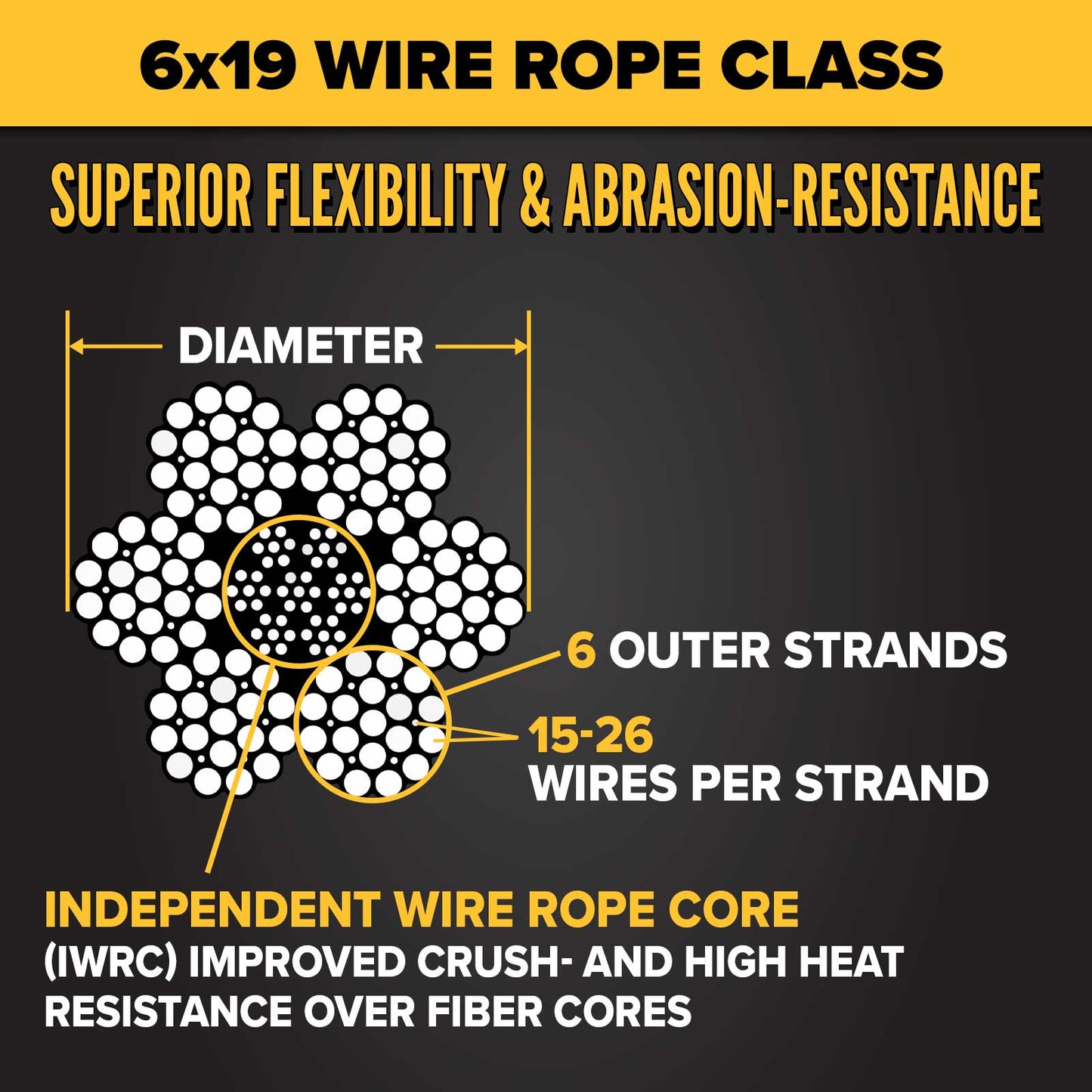

The class of this wire rope is 6x19. These numbers nominally refer to the construction of the wire rope - the number of outer strands around the core and an estimation of the number of wires within each of these outer strands. So for a 6x19 class, the number of outer strands is 6, and the number of wires making up each strand ranges from 15-26.

The independent wire rope core (IWRC) provides more support than a fiber core - it's more resistant to crushing and is better suited for high temperature applications. Their general temperature range is between -40°F / -40°C and 400°F / 204°C.

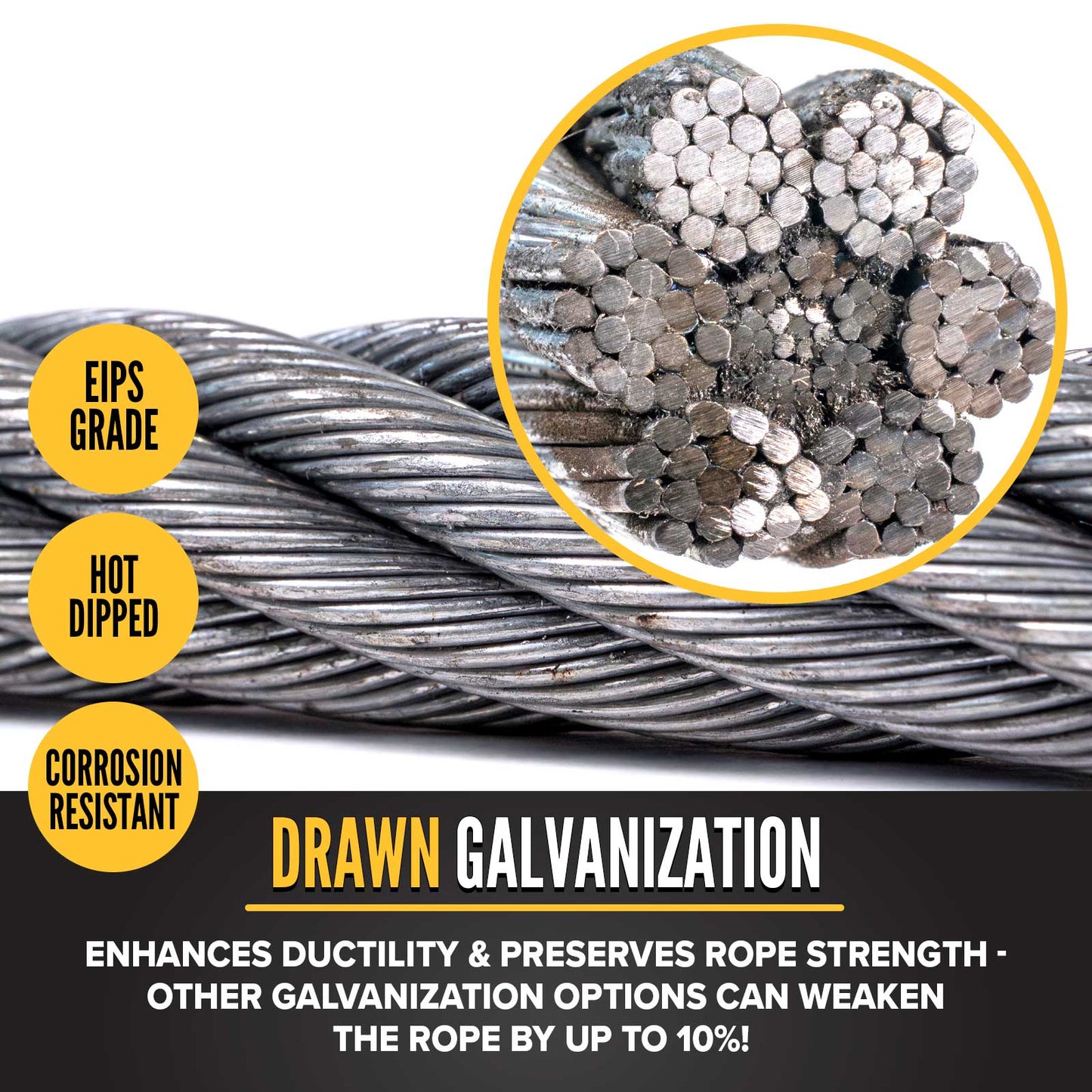

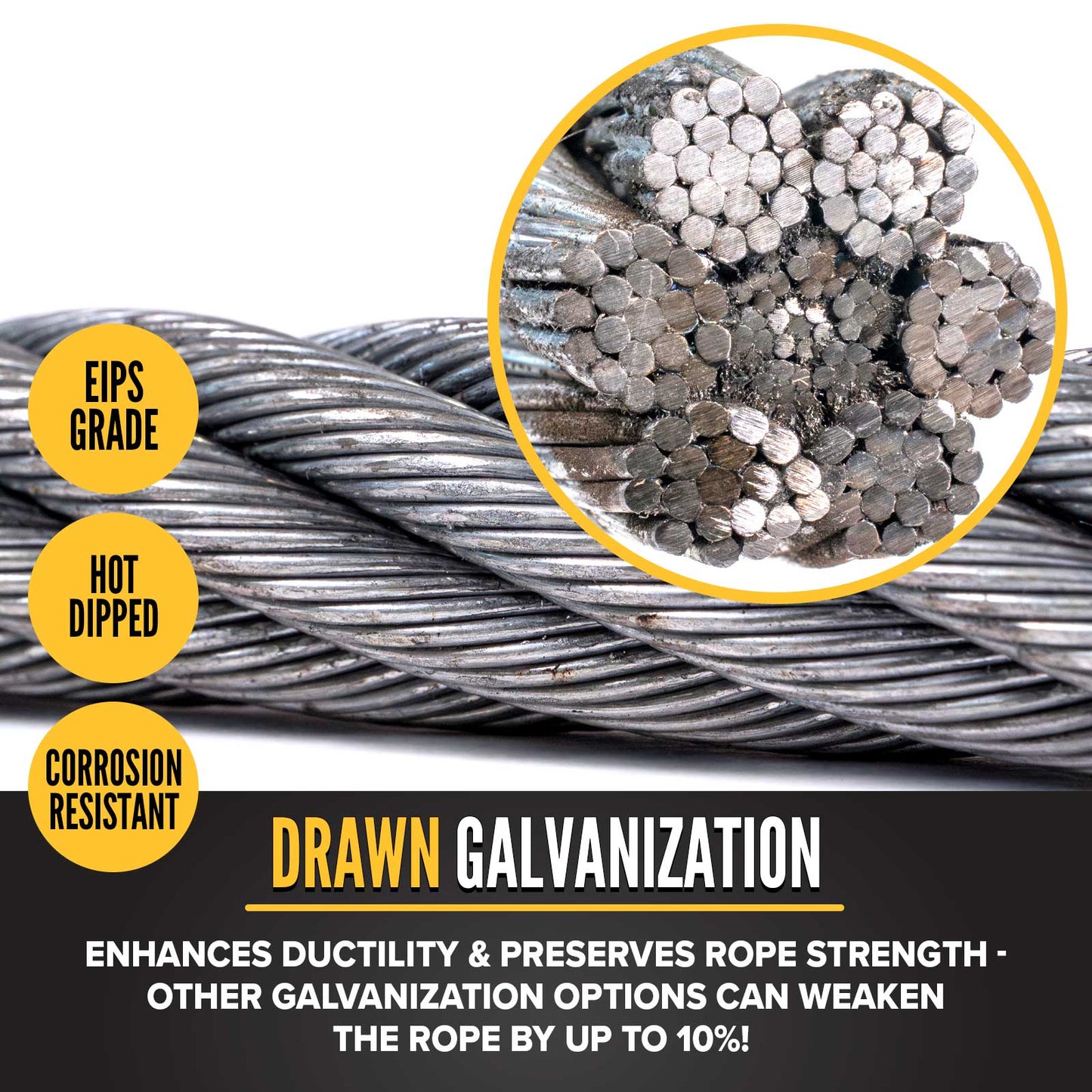

Along with the superior corrosion-resistance compared to a bright wire rope, a hot dip drawn galvanized wire rope offers several other benefits that make it worth the investment.

The most important of these benefits is the strength - the standard galvanization process can weaken the rope by up to 10% of the break strength. The drawn galvanization process does not, so you'll get the same strength as a comparable bright wire rope!

Drawn galvanized also enhances ductility - allowing it to perform better in critical applications - and corrosion-resistance - it won't flake or crack like an electro-galvanized wire might.

Complete your wire rope assembly - we also carry wire rope fittings and rigging hardware, including wire rope clips, turnbuckles, and eye bolts.

Custom wire rope configurations are also available - call or fill out our online form for a quote!

California Residents: WARNING