Crosby® Lifting Clamps

The Crosby® Group considers every lift whether 50 lbs. or a million to be mission-critical. That's why Crosby® has remained committed to top-notch quality and innovation for more than a century. You can trust that the Crosby® plate clamps, beam clamps, and drum clamps we sell are built with the value-added benefits and consistent reliability that have established the brand as an industry leader in markets worldwide.

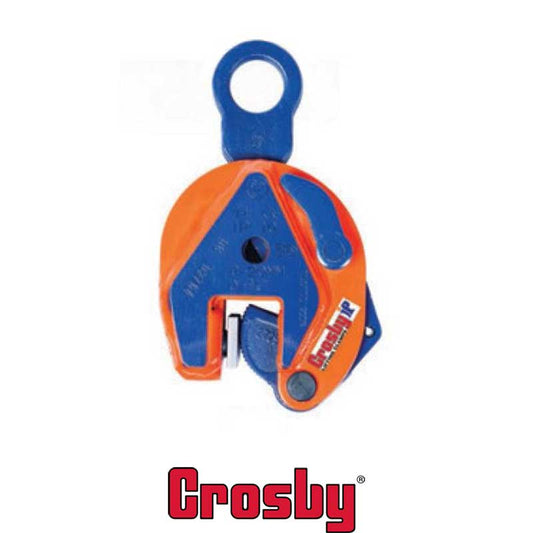

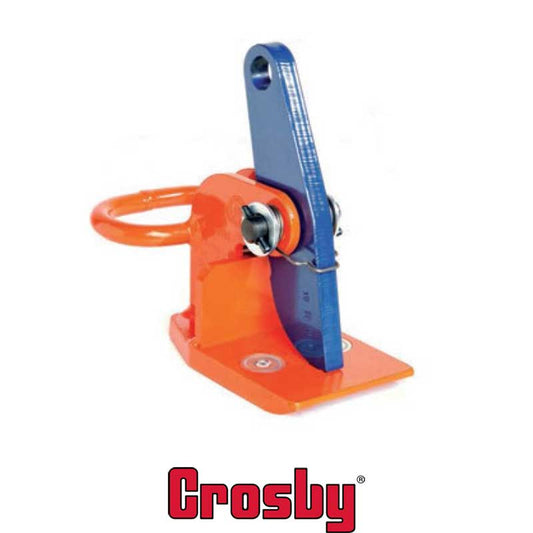

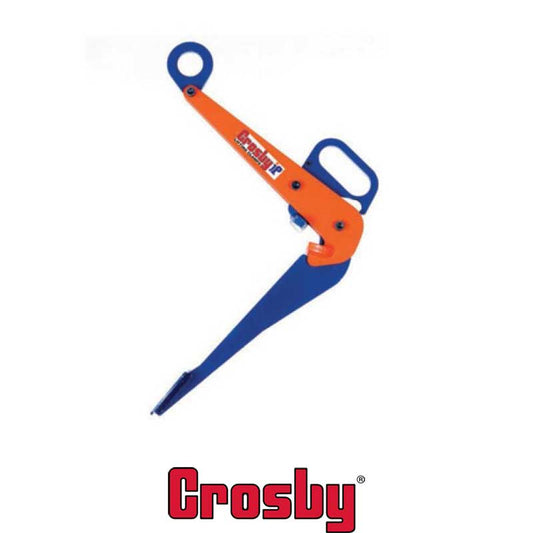

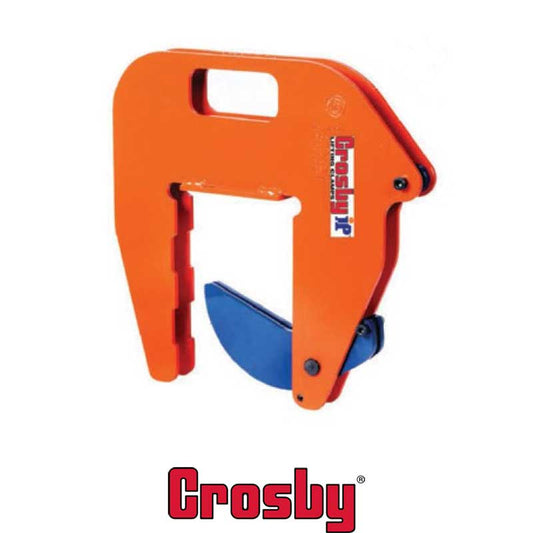

We sell Crosby® clamps with a variety of working load capacities and jaw opening sizes, as well as the following styles: vertical plate lifting clamps, horizontal plate clamps for lifting, beam clamps for lifting, drum clamps, and pipe lifting clamps. Crosby® lifting clamps are produced using advanced manufacturing techniques and are able to withstand abusive field conditions. Each plate clamp, beam lifting clamp, and drum clamp features a welded alloy steel body that is designed to have high-strength while still being lightweight and compact. Where required, sheet clamps and other models are equipped with forged alloy components.

Lifting clamps for plates and additional applications are fitted with programmable Radio Frequency Identification (RFID) chips, assisting in a more automated, efficient, and accurate inspection process. RFIDs are designed for use in conjunction with software programs like Crosby®'s QUIC-CHECK® Inspection and Identification System, which provides a quick reference to information regarding safe use of Crosby® hardware and proper inspection criteria.

Crosby® lifting clamps are individually proof tested to two times the working load limit. Design factor is based on EN 13155 and ASME B30.20. Each plate lifter, along with all clamps we sell by Crosby®, are manufactured in an ISO 9001 facility to ensure compliance with industry standards and procedures. User manual with test certificate is included.

The company name (CrosbyIP), logo, working load limit (WLL), jaw opening, unique serial number, and proof load test date are permanently stamped on the clamp bodies. Lifting clamps for sheet metal, beams, drums, and concrete pipe are Load Rated®, Crosby®'s way of identifying products that have the WLL indicated or affixed to them.

Crosby® strives to develop practical and effective solutions for handling specific hoisting situations, from machine and road construction to jobs that involve pipe laying, windmill energy, or production of steel structures for buildings and bridges.

Also check out our selection of Terrier lifting clamps. Several steel plate lifting clamps are available, including both vertical plate clamp designs and horizontal plate lifting clamps. Also, we have beam, pipe, drum, and specialty versions.

Call us if you have any questions or if you don't see the lifting clamps you need.