Toll Free: 866-444-9990

Español: 844-871-5153

Local: 319-213-9180

Hours: M-F, 7am - 5pm CST

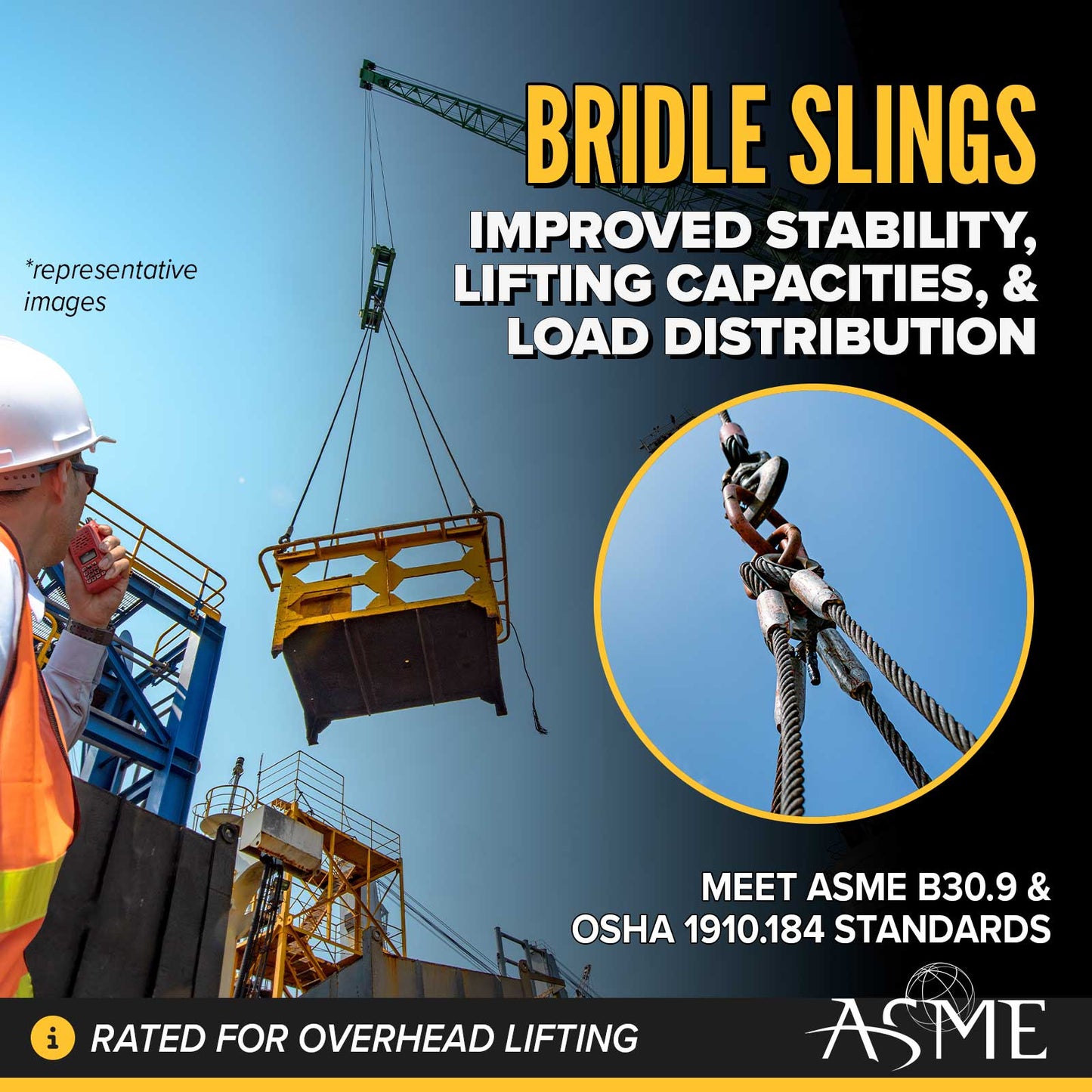

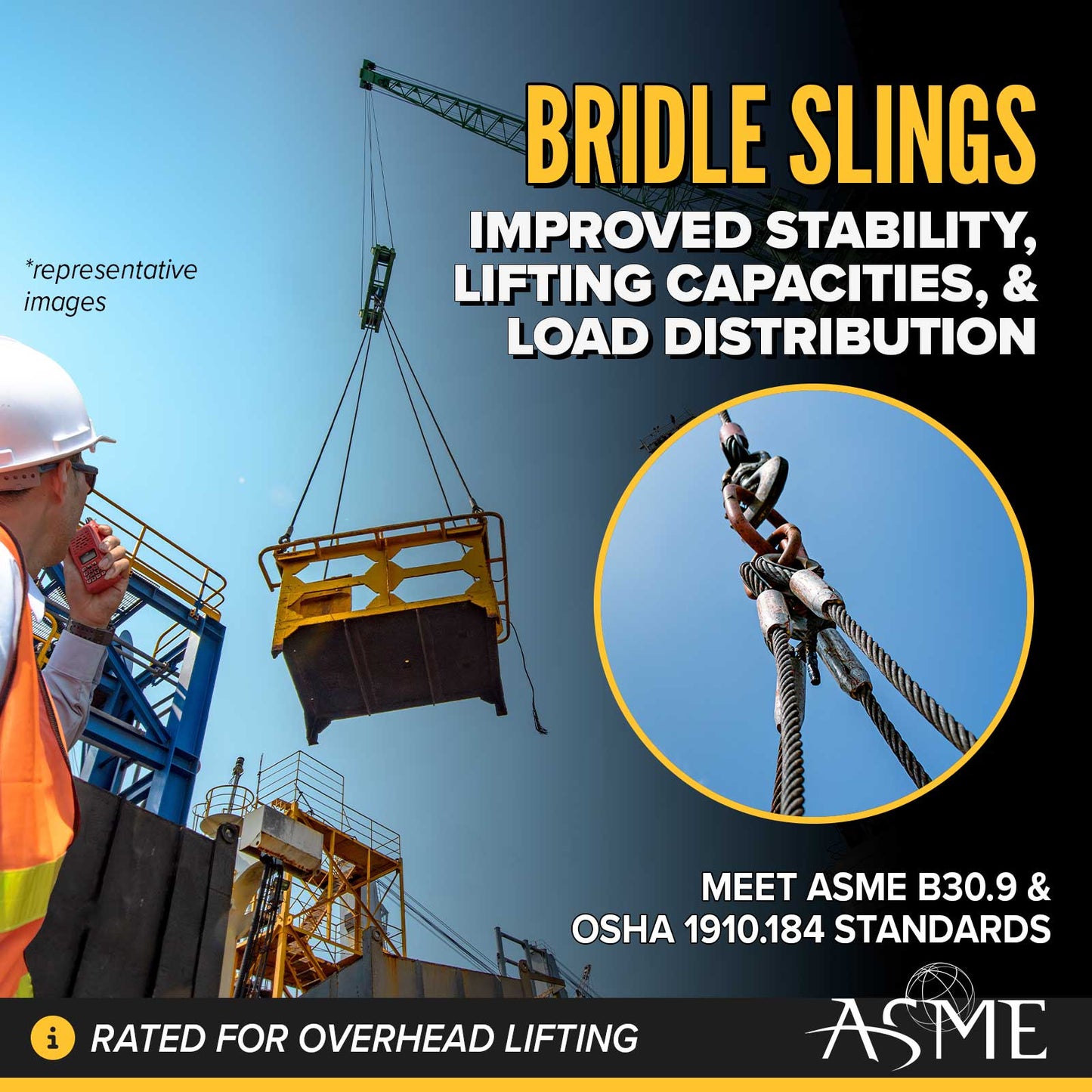

Wire rope slings are a common choice in the lifting industry - they are more cost-efficient than chain slings and more strong, durable, and temperature-resistant than many synthetic lifting slings. Along with these built-in advantages, choosing a 2-leg bridle sling results in additional versatility - when compared to a single-leg wire rope sling, you'll find improved stability / balance, lifting capacities, and load distribution.

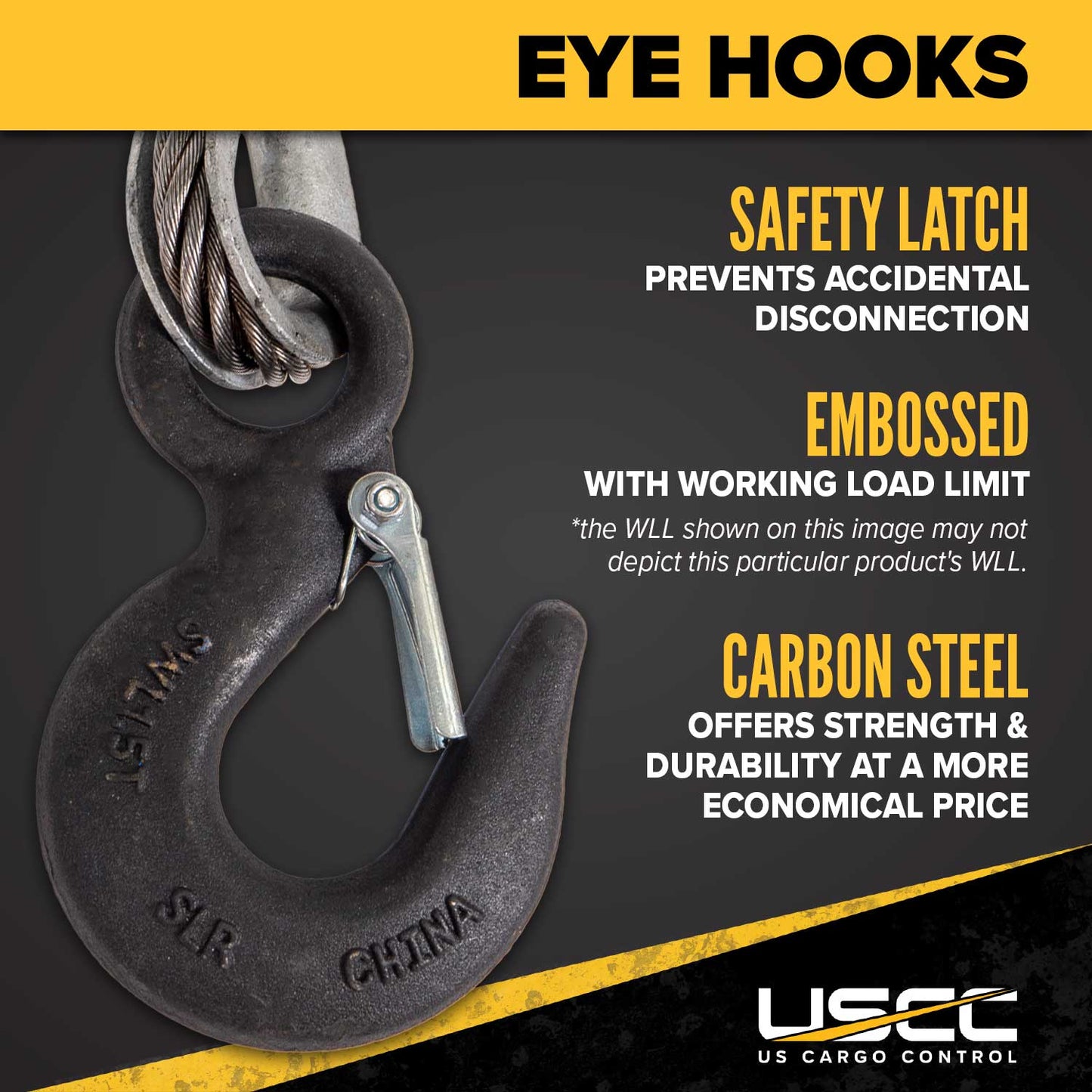

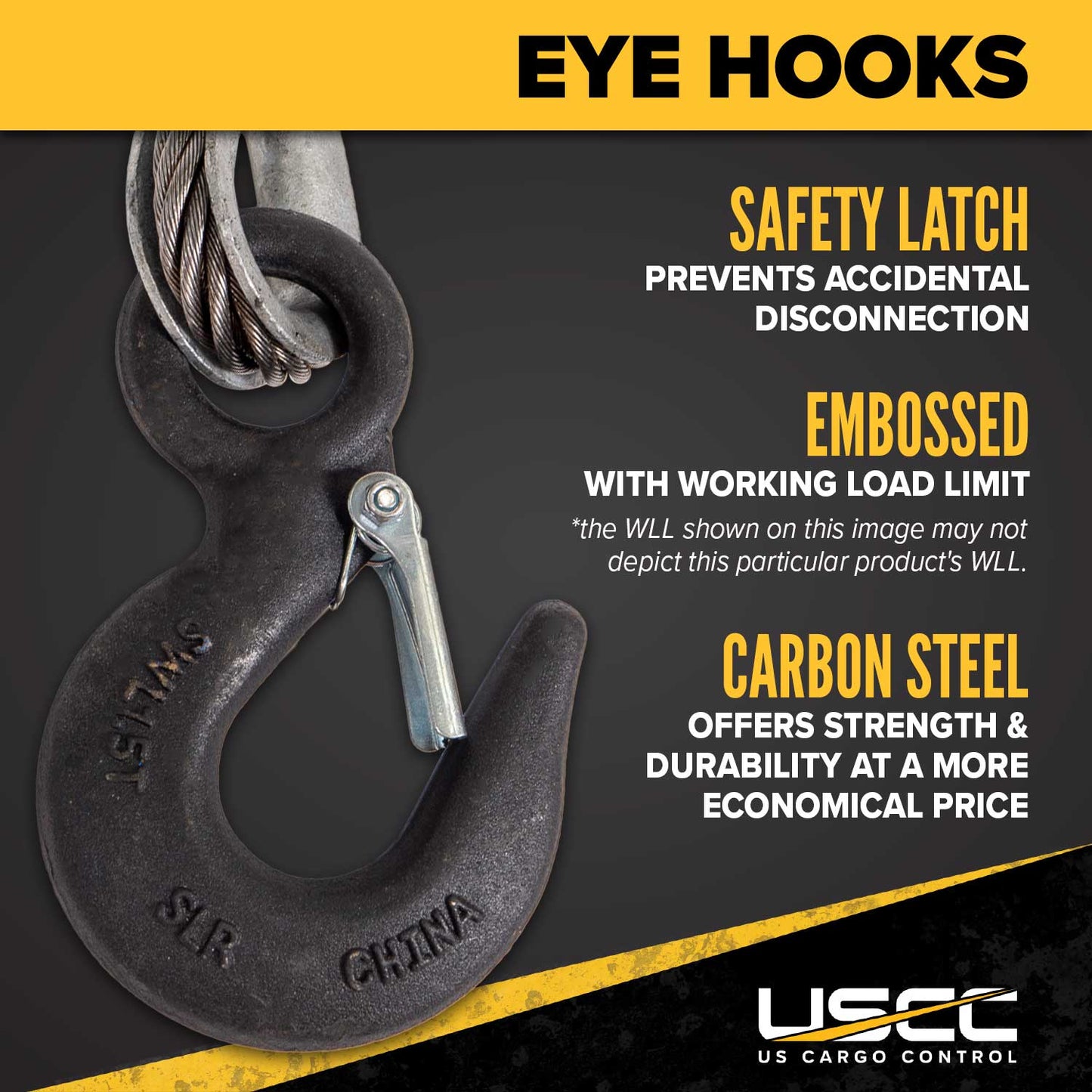

The eye hoist hooks are compatible with a wide variety of attachment points, with a latch to prevent accidental disconnections. For improved safety and ease of use, they are marked with their working load limit.

They are made from carbon steel, which offers a good balance of strength and durability at a more economical price than alloy steel.

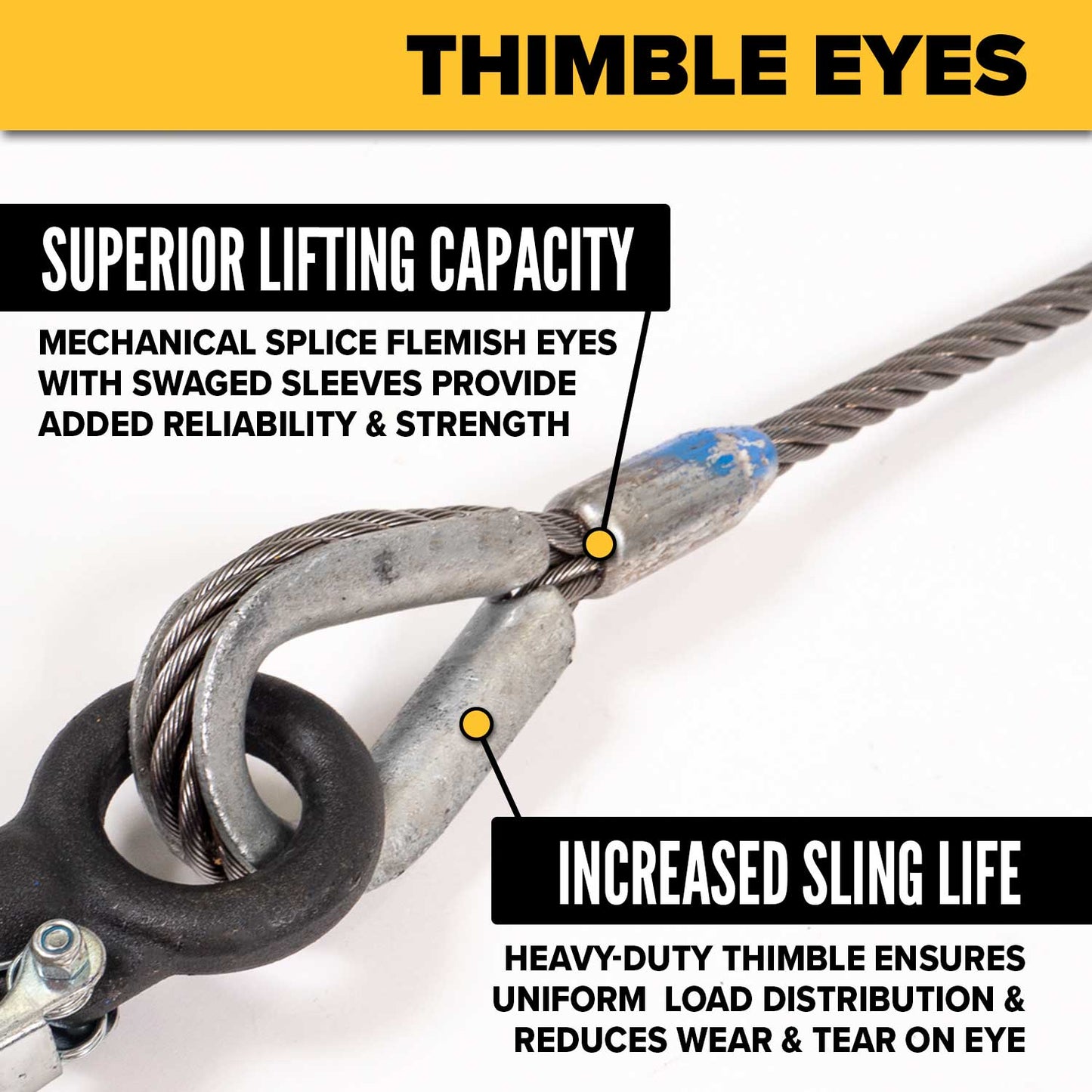

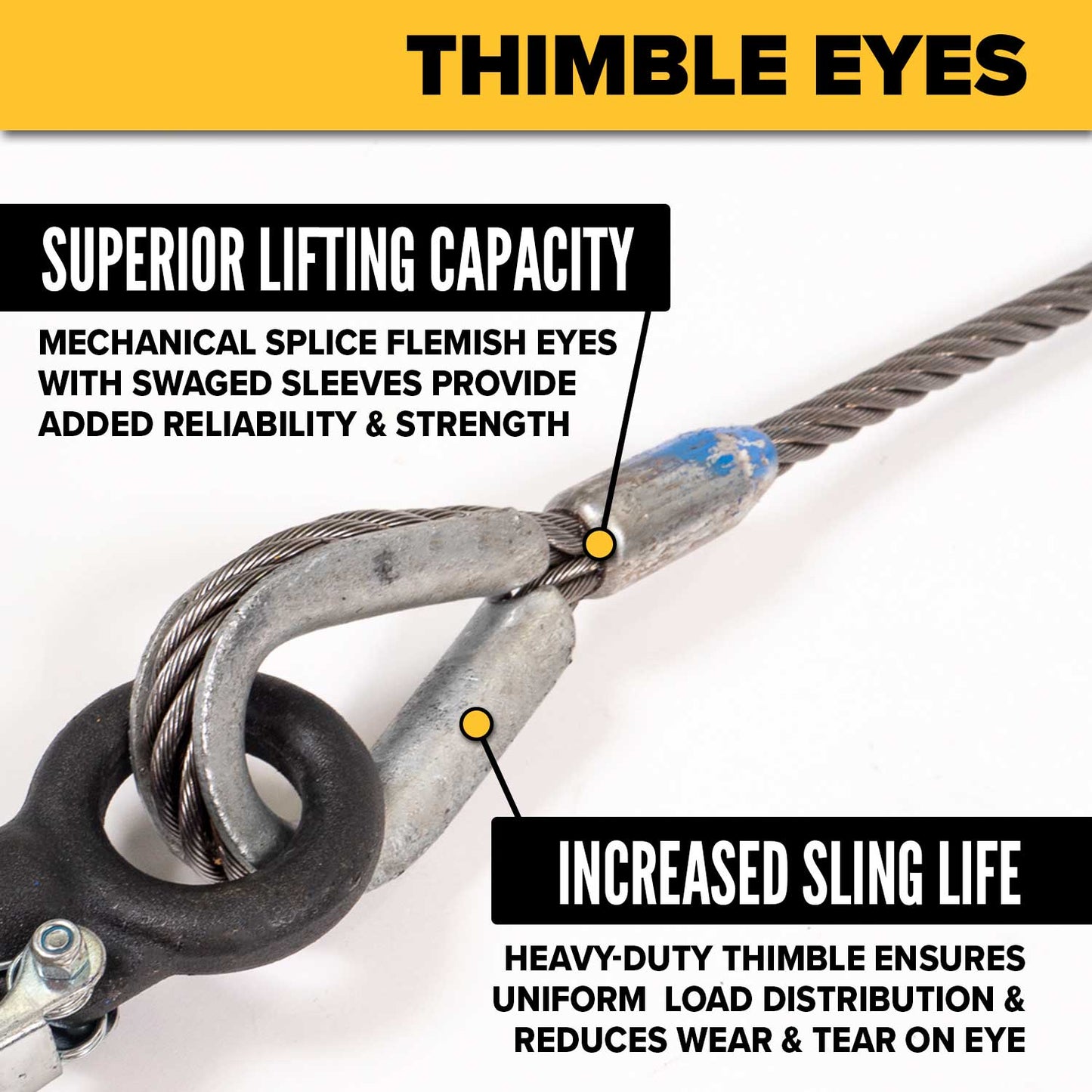

The wire rope sling eyes themselves are made using the mechanical splice Flemish eye configuration and a thimble. Constructed by splitting the wire rope into two parts, looping / weaving them together to create an eye, and securing them with a fitted swaged sleeve, it offers a higher lifting capacity than hand-tucked eyes. The thimble helps to reduce wear and tear, prevent eye deformation, and ensure uniform load distribution.

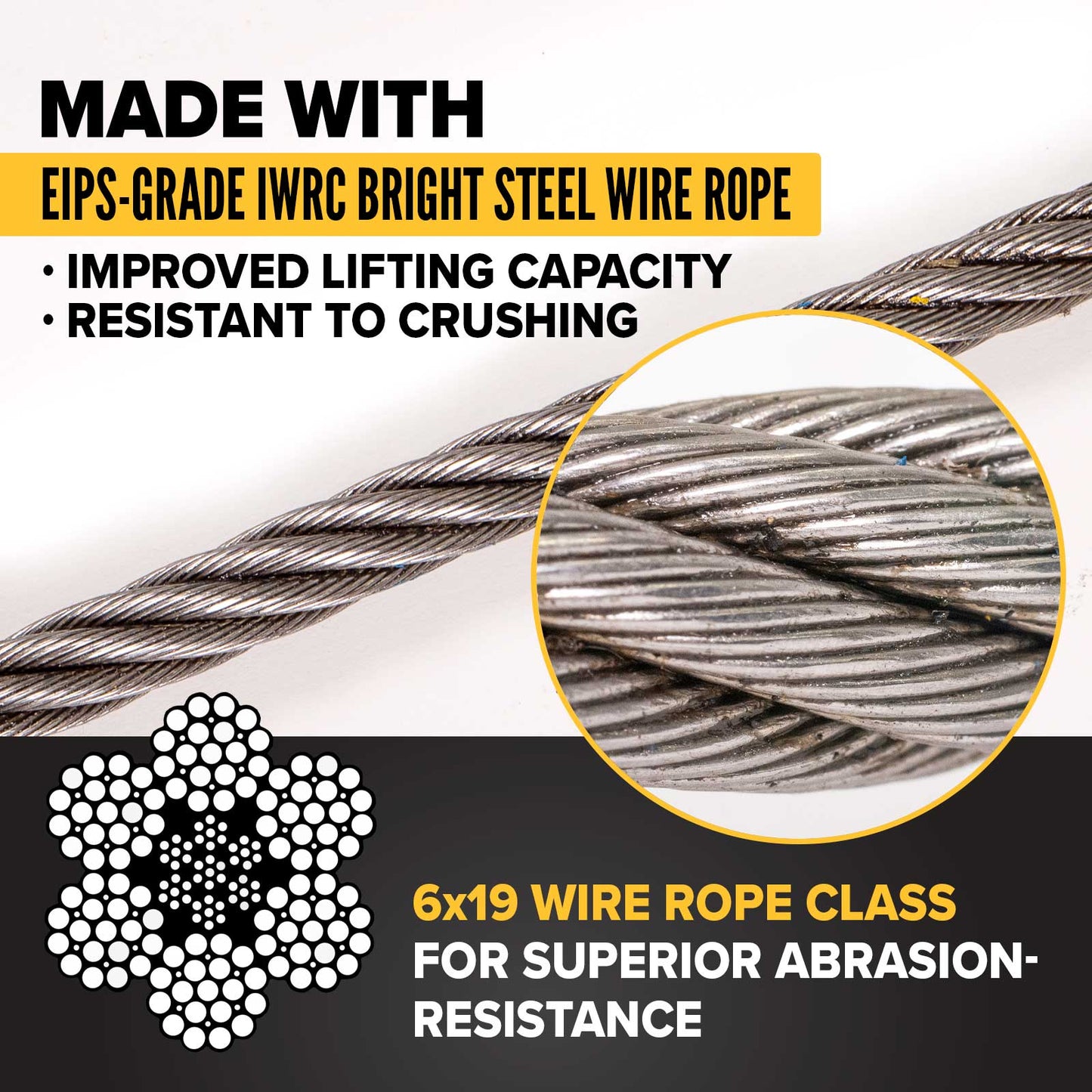

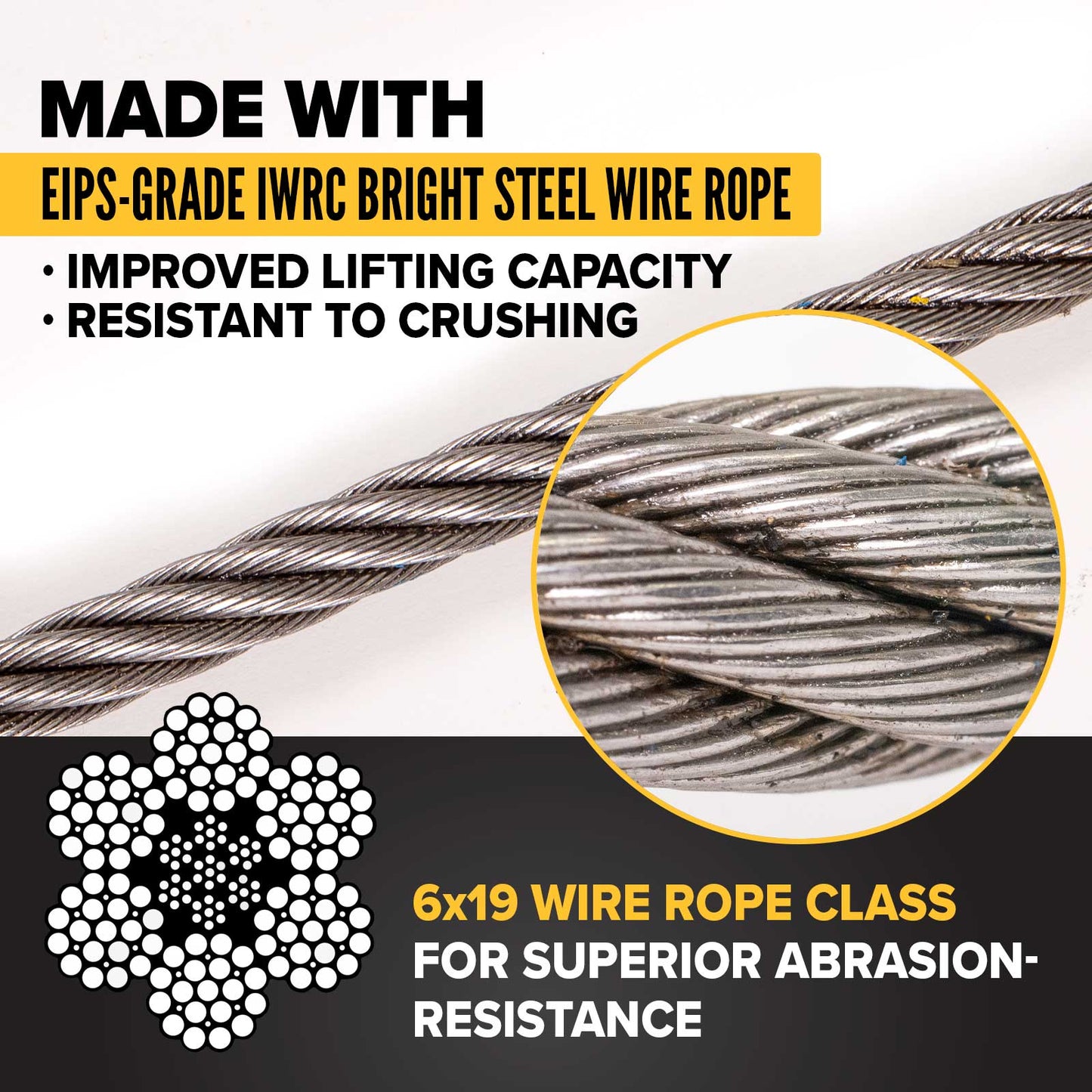

Our wire rope slings are made using EIPS-grade IWRC bright steel rope wire. The EIPS (Extra Improved Plow Steel) refers to the strength of the wire rope - its tensile strength is around 10% greater than an IPS grade, improving the lifting capacity. The bright steel classification means it's uncoated except for a lubricant for basic corrosion-resistance.

IWRC stands for Independent Wire Rope Core. Constructed from durable steel, it's more resistant to crushing / pressure and allows for sling use in higher temperature environments than fiber cores. Fiber cores generally only go up to 180°F / 82°C, while IWRC core slings can handle temperatures up to 400°F / 204°C.

Wire rope classification is a nominal indicator of the rope's construction - the number of outer strands around the core and an estimation of the number of wires within each of these outer strands. This wire rope sling's class is generally 6x19. That means it will have 6 outer strands, with the number of wires making up each strand ranging from 15-26.

The important takeaway from this classification is that it has fewer wires per strand than a 6x36 wire rope sling - resulting in a finished product that is more abrasion-resistant but not as flexible.

Note: This wire rope sling may occasionally be made with 6x36 class wire rope based on inventory levels. If your application requires a 6x19 classification, please reach out and we'll make sure you get what you need!

Complete your setup by checking out our full line of lifting and rigging equipment, including common wire rope sling accessories like shackles, wire rope sling protection, and hook latch kits.

Don't see exactly what you're looking for? We also offer custom lifting and rigging options! Get the perfect wire rope sling for your application by calling or filling out our custom wire rope slings online form to get started. Our team of product experts is here to help answer any questions you may have.

California Residents: WARNING