Lifting Clamps

Types of Lifting Clamps

Lifting Clamps are ideal for handling a variety of load types in a safe and efficient manner. US Cargo Control sells beam clamps, drum clamps, pipe clamps, specialty lifting clamps, and lifting clamp replacement parts.

For plate clamps and sheet clamps, see our section of vertical lifting clamps and horizontal lifting clamps.

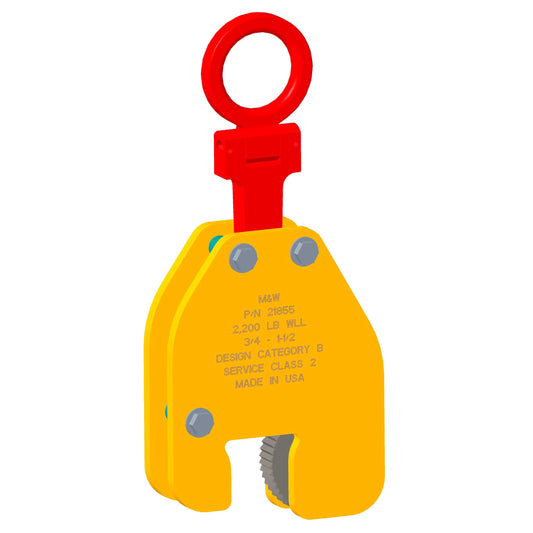

Due to their superior quality and performance, we are proud to sell a large variety of Crosby®, M&W, and Terrier lifting clamps.

If you have any questions on selecting the best lifting clamp for your specific job, don't hesitate to contact our product experts.

What to Consider when Selecting Lifting Clamps

Selecting the correct type of lifting clamp for your specific job is the first step to ensuring safety and efficiency. But other factors you must consider are the weight, hardness, and thickness of the objects you will be handling. Pay close attention to the product specifications and dimensions when selecting lifting clamps. Keep in mind that certain lifting clamps must be used in pairs while others do not.

It's always best to use a lifting clamp with the closest working load limit to what is being lifted. This not only ensures the clamp is working at maximum efficiency, it also reduces wear and increases the life of the clamp. Lifting objects that are 20 percent or more below the weight of what the lifting clamp is rated to handle can negatively wear on the clamp much like overloading it would.

The maximum jaw capacity of the clamp should be as close as possible to the thickness of the material being handled. Lifting clamps with cam mechanisms utilize the weight of the load, so grabbing force is proportional to the weight of the object being lifted. Using a clamp with a jaw capacity closest to your materials thickness will stretch the clamp's spring more and provide the maximum amount of grip to the material being handled.

Meanwhile, some lifting clamps have a threaded screw which require clamping force to be applied manually. This design can be useful for jobs where the clamp needs to be left in place between a series of handling operations.

Certain lifting clamps are designed only for non-sagging materials, while other lifting clamps can effectively handle both sagging and non-sagging materials.

Lifting clamps equipped with non-marring pads will firmly grip materials, such as stainless steel, without scratching them.

Furthermore, object orientation and final placement is important to consider especially when deciding between vertical lifting clamps and horizontal lifting clamps. Many vertical lifting clamps feature a 180-degree turning range, perfect for material that needs to be turned from a horizontal to vertical position. Meanwhile, many horizontal lifting clamps can increase efficiency by handling multiple plates or sheets of material at once.

With a variety of clamping forces, jaw sizes, eye diameters, working load limits, and non-marring pads, US Cargo Control has the lifting clamps you want, when you need them.

Safety Tips for Using Lifting Clamps

When vertically lifting longer objects that require using multiple lifting clamps, consider using a lifting beam with lifting slings connected to each clamp. This will help avoid side-loading and better protect the integrity of the clamps.

To ensure the integrity of lifting clamps, you should inspect them every 1-4 weeks depending on use. Degrease clamps regularly and remove any grit or dirt. Regularly check the tightness of all bolts and nuts and look for any cracks. If any of the clamp's teeth become chipped or broken more than half their original width, the clamp may need to be replaced.

Do not use clamps on objects with surface contamination such as dirt, grease, or scale.

Related Rigging and Lifting Products

We also sell a large variety of rigging supplies & hardware. Check out our selection of wire rope slings, chain slings and lifting chains, polyester round slings, anchor shackles, and much more!

Lifting Clamps by Brand

We are proud to sell lifting clamps from several leaders in the rigging and lifting industry: Crosby®, M&W, and Terrier.

These trusted brands know the importance of safety, performance, and quality. That's why all of their clamps are constructed from the highest quality materials, with the working load limit stamped directly on each lifting clamp for easy visibility.

Don't see the beam clamp, plate clamp, Crosby® clamp, M&W clamp, or Terrier clamp you need? Call us and let us track down the lifting clamp you need.