Lifting Slings

Rigging Slings

Our lifting and rigging slings can be categorized into five general types, based on construction and design: nylon, plasma, polyester, wire rope, and chain. Some styles, such as the eye and eye sling and the endless sling, are available in both nylon and polyester.

Because US Cargo Control cargo lifting straps need to accommodate the requirements of a diverse range of lifts, all web slings are manufactured with only the highest quality materials. From USA-made nylon slings to heavy duty chain slings, you can count on US Cargo Control as a trusted lifting sling supplier.

Sling Proof Testing

All of our crane rigging slings are eligible for proof testing prior to shipment. Our policies regarding proof testing varies by the type of sling:

Plasma®, High Performance, and Chain Slings

All plasma®, high performance roundslings, and chain slings are automatically proof-tested prior to shipment at no extra charge.

Nylon, Polyester, and Wire Rope Slings

Wire rope and synthetic slings do not automatically come with proof testing. It can be requested for a nominal charge based on the size of the sling. Call to place your order and request proof testing from your product expert.

Nylon Webbing Slings

Nylon lifting slings have a strong, dense construction, but are still pliable enough to conform to the object being lifted. This flexibility makes nylon a good choice for delicate or finished equipment that must be handled with care.

Nylon lift straps do stretch - approximately 6-8% of their length - so they may not be suitable for some uses. They also absorb liquids, so acids can affect the strength of the fabric.

Our nylon synthetic slings are constructed of industrial-grade webbing with a rating of 9,800 lbs. per inch. Each has a tag sewn in with information about working load limits for different hitch uses.

If you need extra protection at points of contact, reverse eye slings have CORDURA® wear pads on both eyes. This fabric creates a tougher surface that resists cutting and abrasion.

Polyester Slings

Like nylon lifting slings, polyester round slings are also made from a synthetic, tough, web-like fabrication. However, a polyester sling has much less stretch (approximately 3%), so it's ideal for applications that require strength but very little stretch.

Unlike nylon, polyester hoist slings are safe for use where bleaching agents or acids are present.

They are constructed with a color-coded jacket according to weight ratings, so safe use guidelines are easy to follow. Manufacturers' information regarding size, type and capacity is also indicated on an identification tag sewn on the strap.

Plasma® Slings

Plasma® eye & eye slings are well-suited for many lifting applications. Constructed from a high-strength synthetic material, Plasma® lifting slings can be used in many of the same applications as wire rope.

The advantage of Plasma® is that it is more lightweight and flexible. You can get a sling with the same strength as a wire rope sling at a fraction of the weight. They don't recoil when they fail, and they are corrosion-resistant!

Made in the USA, each rigging strap is individually proof-tested to 200%.

High Performance Roundslings

Unleash the remarkable synergy of superior strength and lightweight design with high performance roundslings. These load-conforming synthetic slings are crafted using advanced inner fibers and shielded by a protective outer jacket, delivering an ideal blend of safety and efficiency for all your rigging and lifting requirements.

They offer low elongation – ideal for low-headroom applications - and also help to streamline your rigging setup. The reduced weight (compared to most other options) means fewer riggers are needed and the process is faster.

Depending on your application, there are several HPRS styles to choose from, including UHMPE, Twin-Path®, Single-Path, and Sparkeater®. These are made in the USA and have a design factor of 5:1.

Wire Rope Slings

Wire rope slings offer durability and a high tensile strength for heavier loads, but are lighter weight and more cost-efficient than chain slings for lifting. They come in various strengths and constructions, so there's something for many applications.

Categories of wire rope are based on how many wires make up a strand and how many strands are wrapped around a core. For example, a 6x37 wire rope is 6 strands of 37 wires. Variations in these numbers determine a wire ropes' resistance to abrasion and flexibility. More wires increase flexibility and resistance to kinks, but also makes it more prone to abrasion wear. Fewer wires will make the wire rope larger in diameter, with a higher abrasion resistance, but will also reduce the slings' lifting flexibility.

Wire rope slings are built for durability, but it's important to inspect wire rope regularly as abuse or misuse can damage it, making it unsafe. Our wire rope slings are made to order.

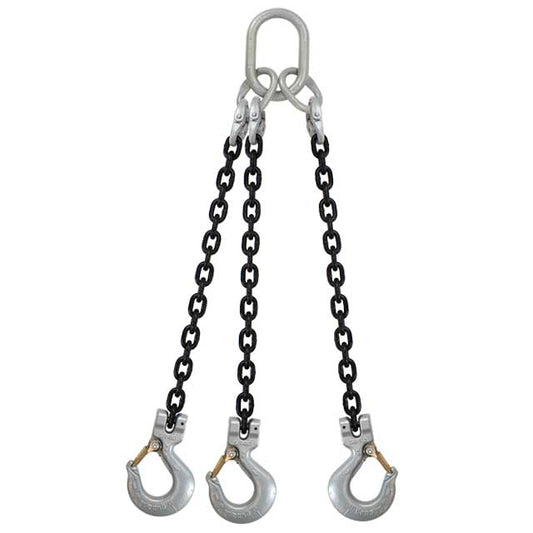

Chain Slings

Chain lifting slings are ideal hoisting slings for rugged duties and work environments and may sometimes be referred to as crane slings or crane lifting straps.

Resistant to both cutting and abrasion, a chain sling's lifting capacity can be maintained even in high temperatures (up to 400 degrees Fahrenheit/204 degrees Celsius) with no reduction of strength.

Made from a high strength alloy steel, chain slings are generally constructed from Grade 80 steel, which is considered the industry standard. Grade 100 chain for a lift sling is also gaining in popularity, as it offers about 25% more strength per chain diameter, yet is lighter weight than Grade 80. All of our chain slings for rigging are available in Grade 100 chain upon request.

Another advantage of chain slings is the number of designs and fittings that can be used to create custom sling assemblies for nearly any lift. Single leg, double leg, basket, double basket, endless basket and double endless are just a few of the chain lifting sling options available.

All slings are completely customizable and are automatically proof-tested prior to shipment at no extra charge.

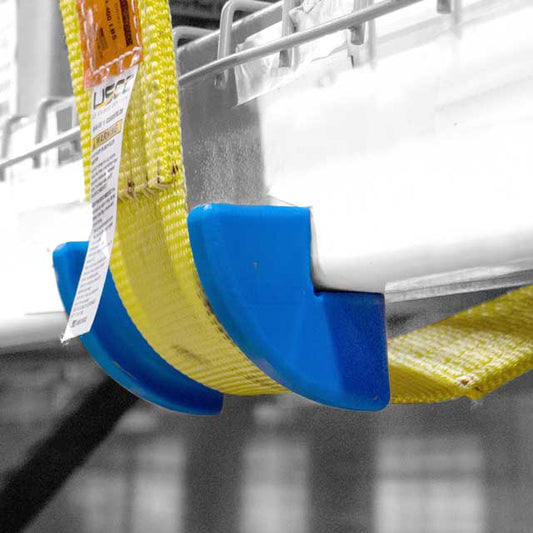

Lifting Sling Protection

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage." - ASME B30.9 (2021) 9-5.10.4(d)

Protect your sling and your load during the lifting process with sling protectors. These accessories not only extend the lifespan of your sling, they also reduce the potential for employee injury during the lifting process.

Questions?

Need assistance determining what the best lifting straps or slings are for your application? Looking for a customized solution? Check out our How to Choose a Sling guidelines or contact our expert sales team. They'll be happy to answer questions about any of our products!