Toll Free: 866-444-9990

Español: 844-871-5153

Local: 319-213-9180

Hours: M-F, 7am - 5pm CST

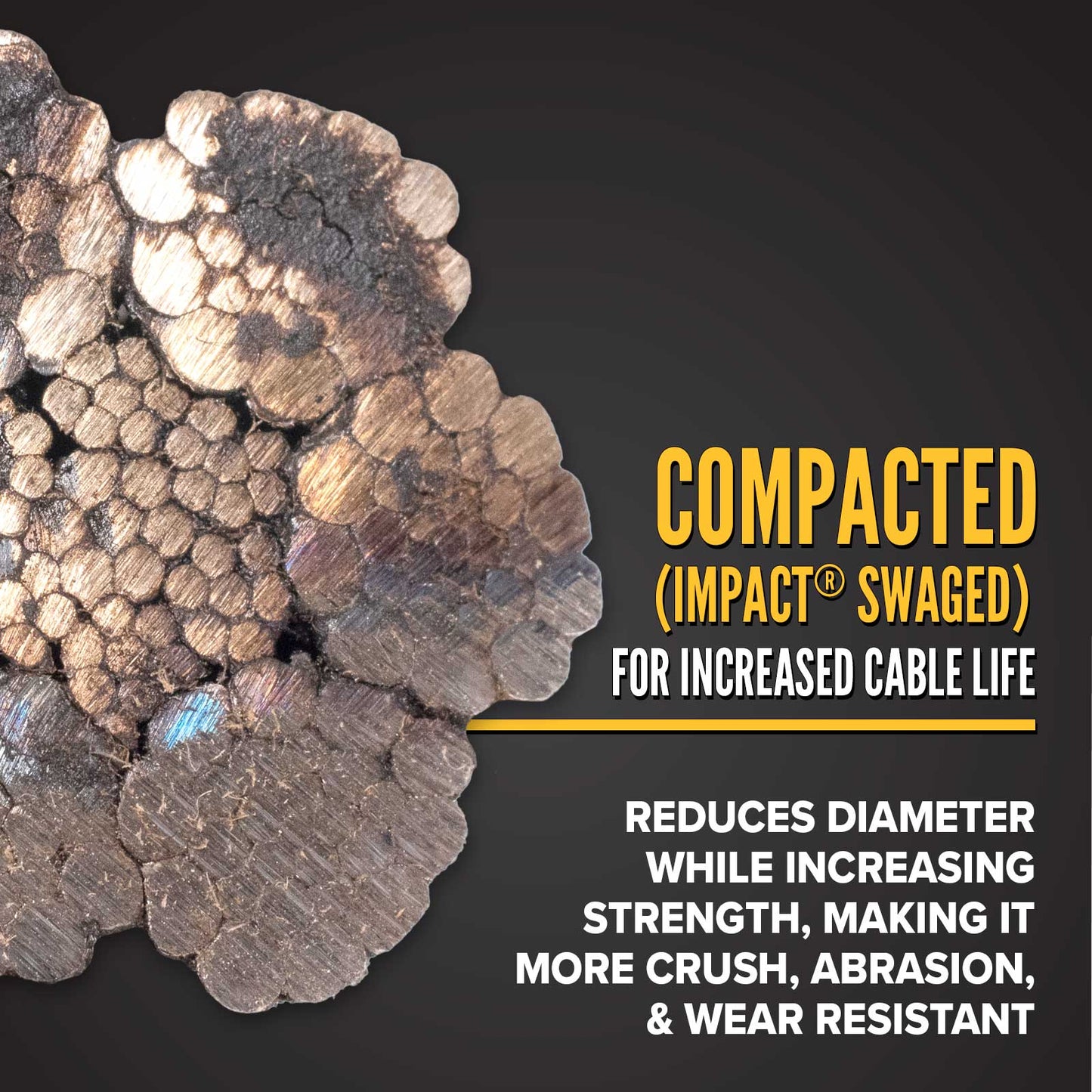

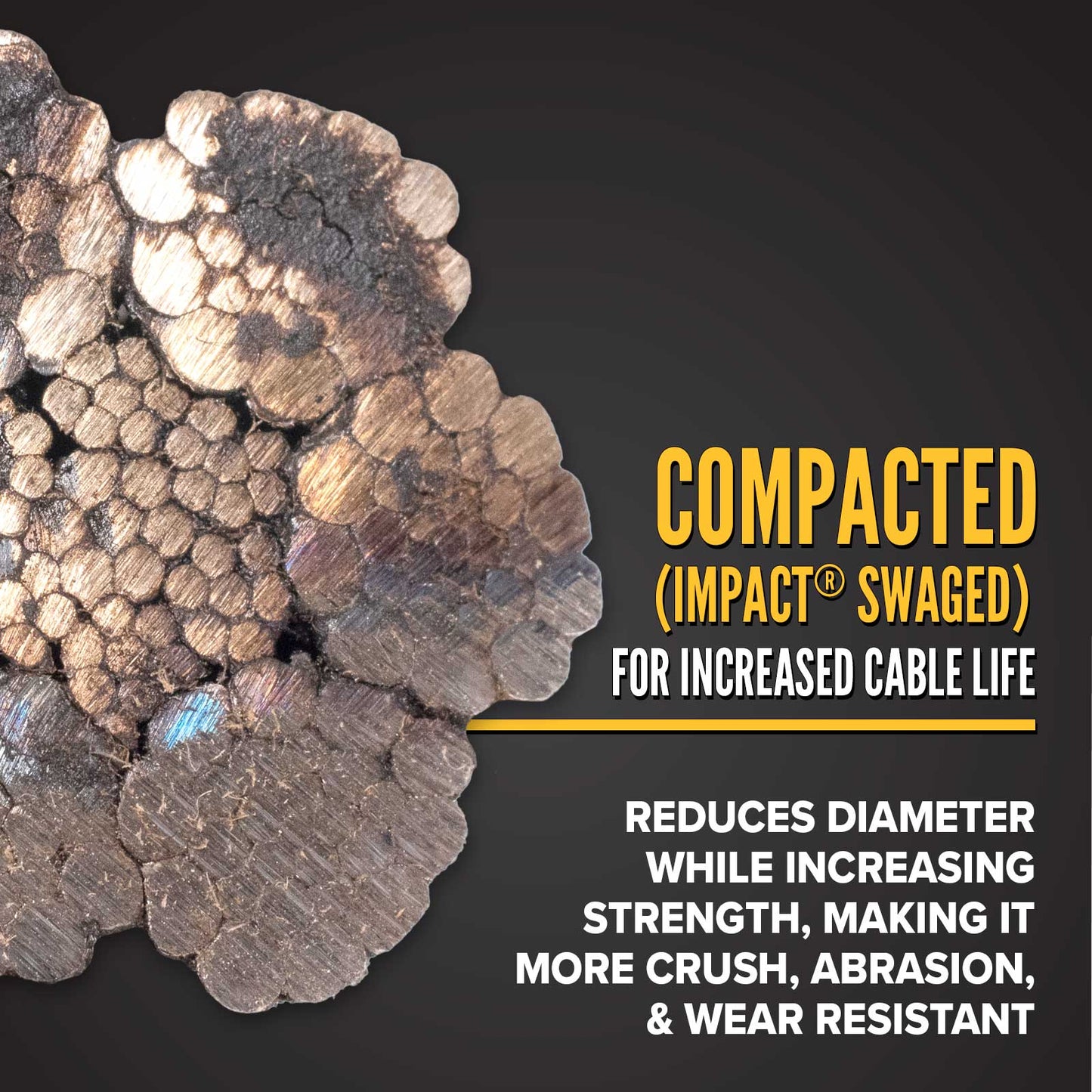

Impact® swaged 6x26 bright wire rope is compacted, meaning the diameter was reduced by a swager machine as part of the manufacturing process. This offers a number of different benefits, including greater strength (when compared to a non-compacted 6x26 wire rope of the same diameter) and flexibility, as well as resistance to crushing, wear, pig tailing, and kinking! It even allows it to spool better. All of these features combine for a longer wire rope service life.

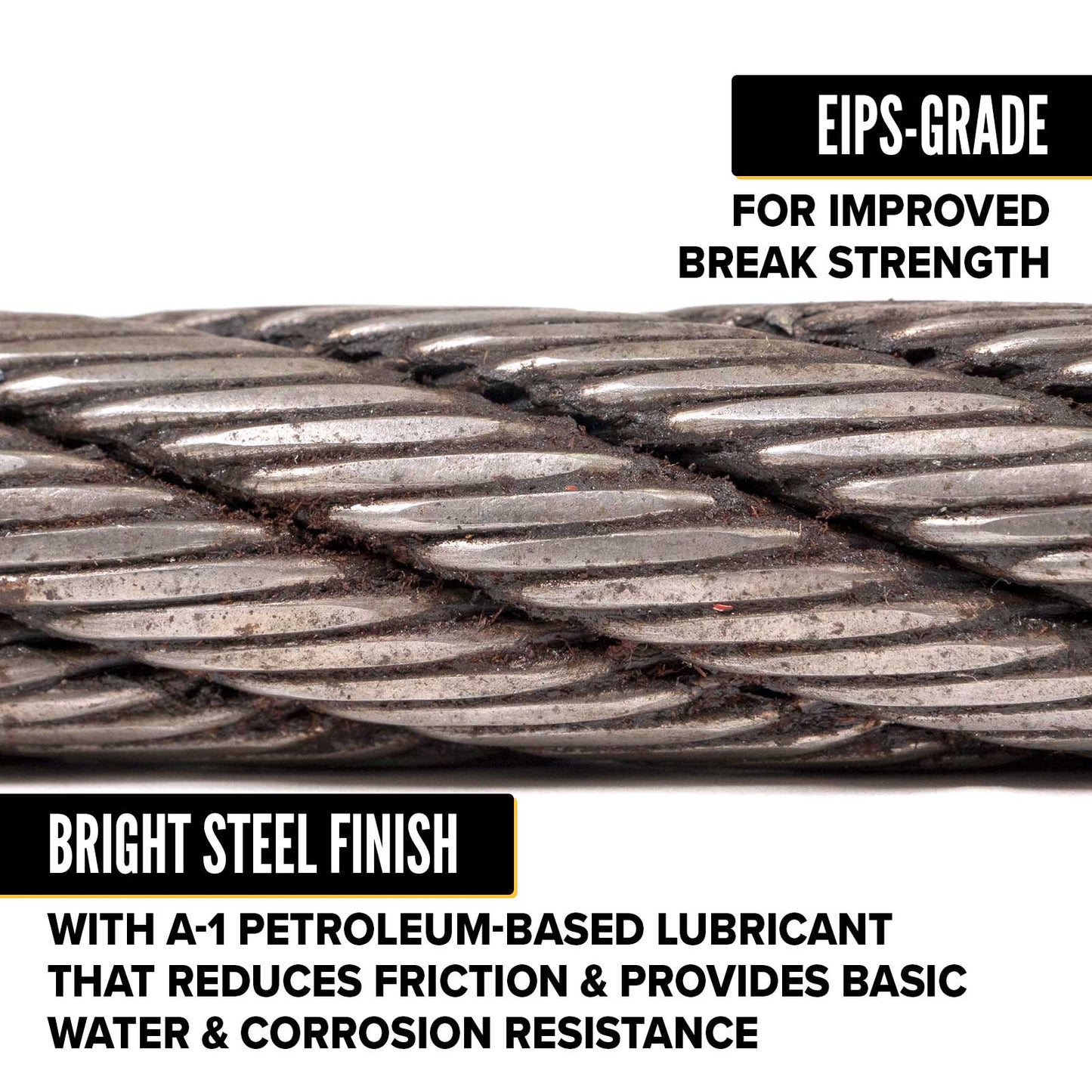

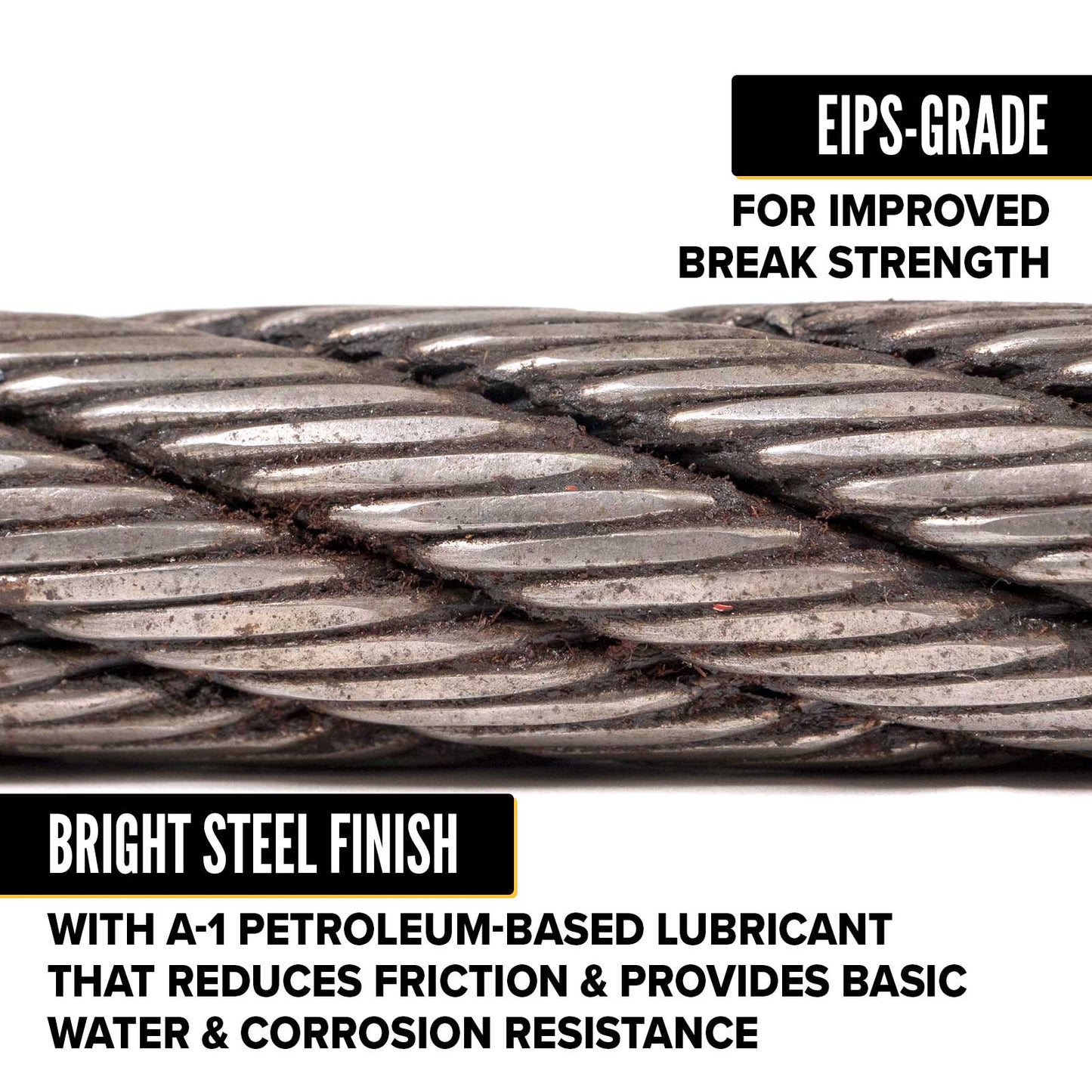

Our wire rope is made using EIPS-grade cable. EIPS (Extra Improved Plow Steel) refers to the strength of the wire rope - its tensile strength is around 10% greater than an IPS grade, improving the break strength.

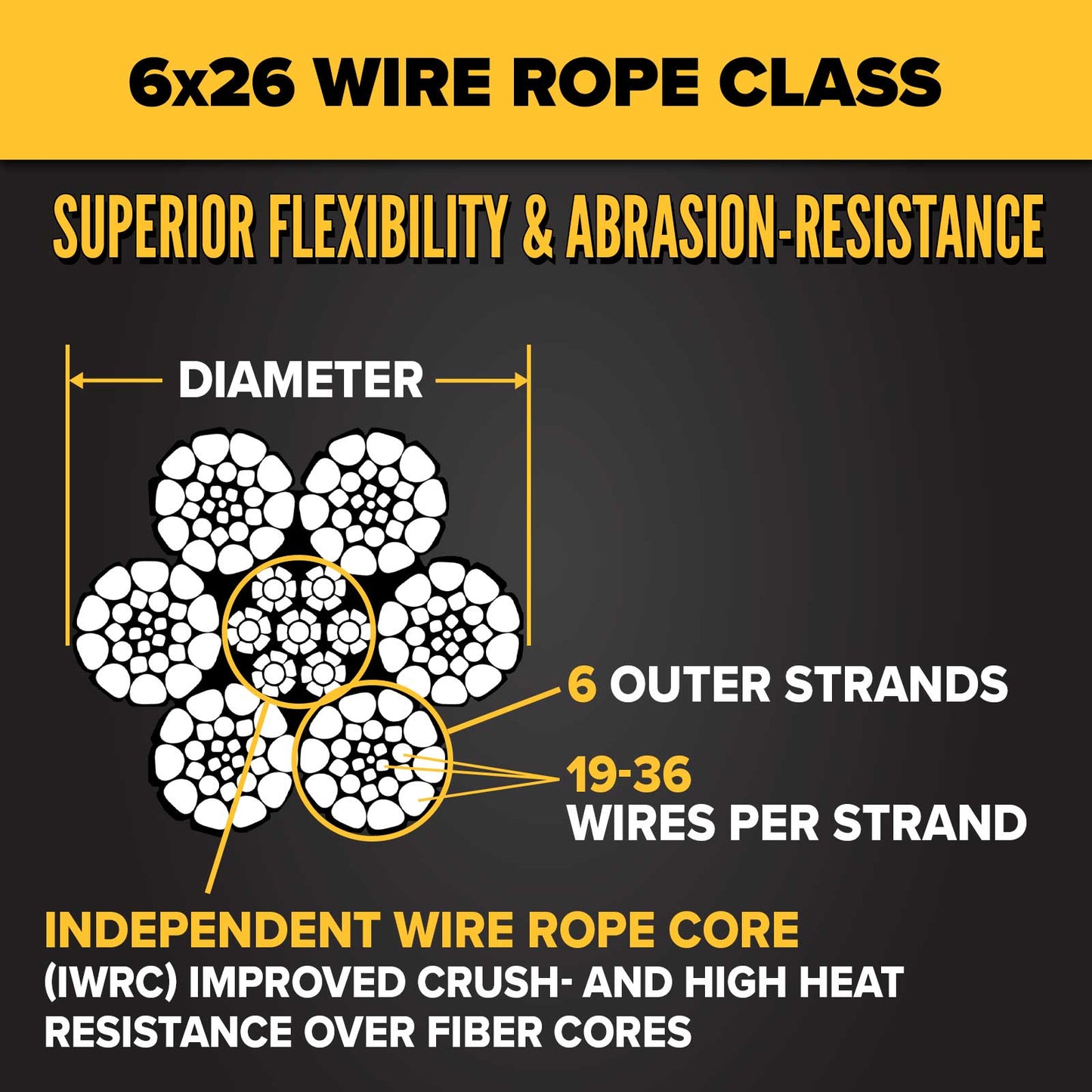

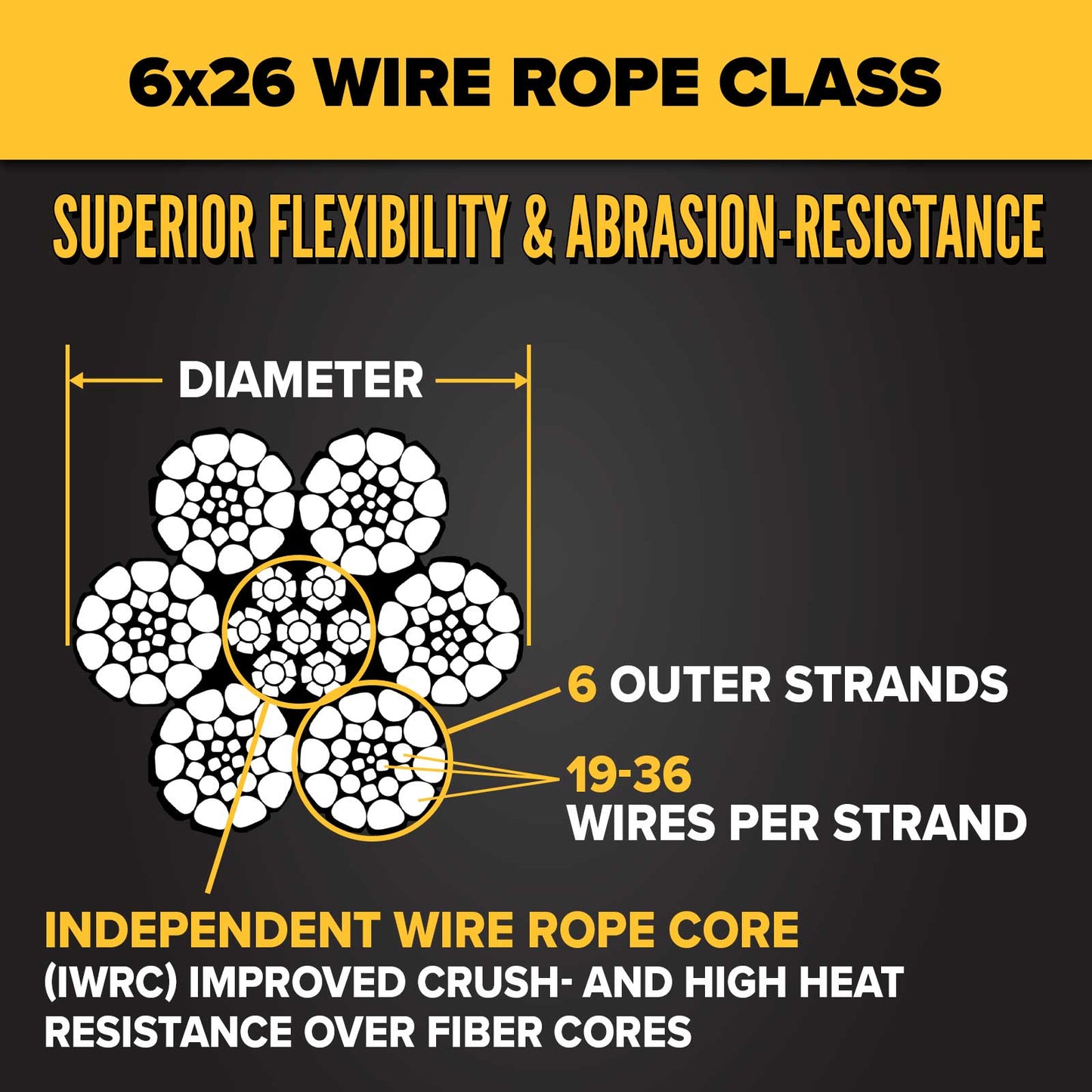

The class of this wire rope is 6x26. These numbers nominally refer to the construction of the wire rope - the number of outer strands around the core and an estimation of the number of wires within each of these outer strands. So for a 6x26 class, the number of outer strands is 6, and the number of wires making up each strand ranges from 19-36.

This product has a bright steel finish, which means it's uncoated except for an A-1 petroleum-based lubricant. This lubricant offers basic corrosion- and water-resistance and reduces friction to protect the rope. The lubricant is applied to both internal and external wires for more in-depth protection.

The independent wire rope core (IWRC) provides more support than a fiber core - it's more resistant to crushing and is better suited for high temperature applications. Their general temperature range is between -40°F / -40°C and 400°F / 204°C.

Does this wire rope come as one length? Yes, the quantity you add to the cart will be provided as one unbroken length of rope. So if you add this to the cart with a quantity of 1000, you will receive one 1000-foot long rope.

Can I order multiple separate lengths? Yes. For example, if you need two 1500-foot lengths of rope, you would set the quantity to 1500 and then add that to the cart twice. For each separate instance you add this to the cart, you will get a separate length of rope.

Can I order lengths less than the minimum order quantity if when combined they will be greater than the minimum order quantity? Yes - please call to speak to one of our product experts to place this order.

Complete your wire rope assembly - we also carry wire rope fittings and rigging hardware, including wire rope clips, turnbuckles, and eye bolts.

Custom wire rope configurations are also available - call or fill out our online form for a quote!

California Residents: WARNING