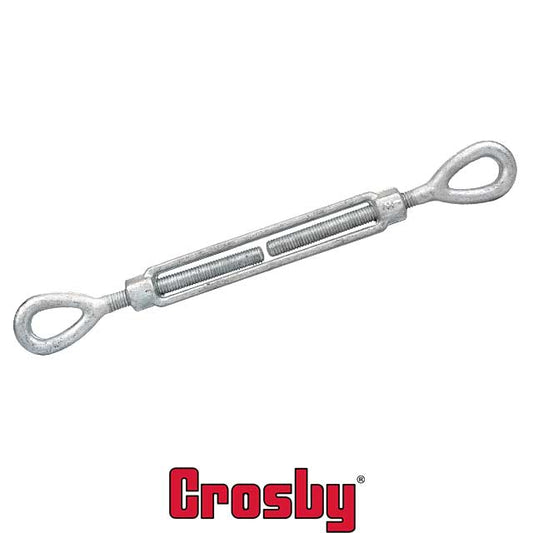

Crosby® Turnbuckles

Crosby Turnbuckles

When you use a Crosby product, you expect superior performance and dependability. Like their other products, Crosby turnbuckle assemblies deliver. Constructed from special bar forging quality steel, they are perfect for use in a wide range of applications, including construction, tower work, suspension bridges, and more.

NOTE: Turnbuckles are recommended for straight or in-line pull only.

Crosby® turnbuckles meet or exceed all requirements of ASME B30.26, including identification, ductility, design factor, proof load, and temperature requirements. They also meet other critical performance requirements like fatigue life, impact properties, and material traceability.

The theoretical reserve capability of each Crosby turnbuckle is at least 5x the WLL set by Federal Specifications FF-T-791b, Type 1, Form 1, Class 7, and ASTM F-1145, except for those provisions required of the contractor.

Crosby Turnbuckle End Fittings

Our Crosby turnbuckles are available in several end fitting combinations: Jaw & Jaw, Jaw & Eye, and Eye & Eye.

All end fittings are quenched and tempered or normalized, allowing for greater durability at all temperatures. Since end fittings handle the bulk of the load-bearing and are regularly exposed to high-stress applications, this additional strength is essential.

Enhanced Crosby® Construction

When it comes to turnbuckle construction and testing, Crosby is known for going above and beyond.

Stress-Minimizing Threading

The turnbuckle bodies have UNC threads, while the end fittings use a modified UNJ thread, reducing the stress at the root of the thread.

Heat-Treated Steel

Each Crosby turnbuckle is heat-treated using Crosby's perfected methods. Their processes are designed to fully develop the turnbuckle's strength, as well as to fortify the grain flow of carbon and alloy forgings.

This reduces the risk of a catastrophic failure, improving the safety of your jobsite. As an additional failsafe, their turnbuckles will begin to deform if overloaded, providing a warning before ultimate failure.

Hot-Dip Galvanized Finish

Components have a high-quality, hot-dip galvanized finish for corrosion resistance and long-term sustainability.

Comprehensive Strength Testing

Tested at 1.5 times the working load limit for a minimum standard of 20,000 cycles, Crosby turnbuckles are fatigue-rated, meaning they were found to have increased fatigue-resistance. This testing helps Crosby to identify and provide long-lasting products, and in this case ensures the turnbuckles meet the requirements of Euronorm standards for fatigue.

Their proof load is 2.5 times the working load limit, while their ultimate load is 5 times the WLL.

Stamped for Traceability

Crosby forges its logo, as well as the size and Product Identification Code (PIC) into each turnbuckle component. The PIC helps maintain material control from the steel mill through the manufacturing process; each Crosby turnbuckle is individually PIC-coded to allow traceability to its respective date of production and material certification.

Questions?

If you have questions about any of the Crosby turnbuckles we sell, get in touch with one of our product experts today. They can provide a bulk pricing quote, help identify which turnbuckle you need, and even place an order for you.

Looking for other Crosby® rigging hardware? We carry shackles, lifting clamps, chain slings, and more.