Wear Pads

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

-

starting at$0.00

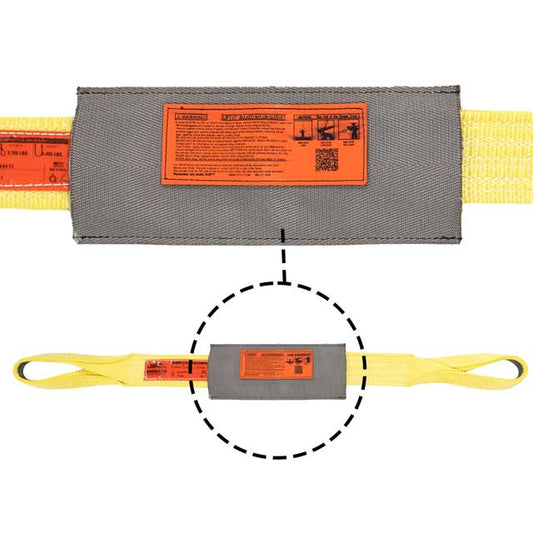

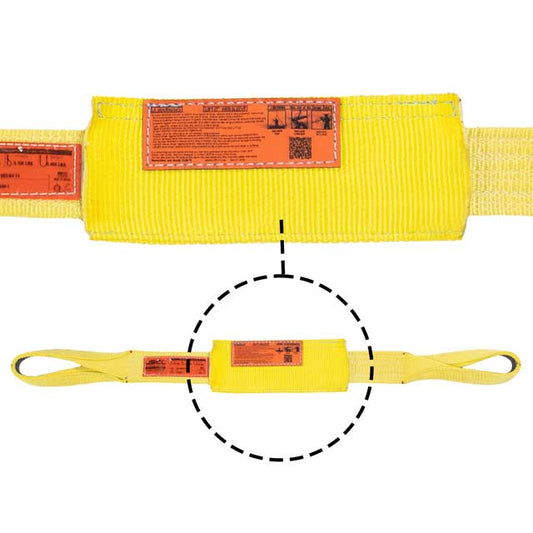

Sling Protection Sleeves

Our made-in-the-USA lifting sling protectors provide protection to both sides of the sling. They are also adjustable along the sling's length. This makes setup easy and allows for quick sling inspections.

These sleeves come in several styles and materials, and can be used with multiple sling types.

Sleeve Material

Lifting sling protection sleeves come in two materials: nylon webbing or Cordura®.

Nylon webbing sleeves help to protect your slings from damage, but will provide little, if any, abrasion-resistance. They also keep your load from being harmed by your sling.

Sleeves made from Cordura® fabric, on the other hand, do offer abrasion-resistance. Cordura® is extremely tough and long-lasting, making it an ideal choice for sling protection.

Neither sleeve material is rated for cut-resistance. If you require protection against cutting for your lifting application, check out our CornerMax® sleeves!

Sewn Sleeves

Sewn sleeves are usually chosen for long-term use on one sling. Both sides are sewn together, which makes removal difficult.

Sewn Sleeve Sling Compatibility

Sewn sleeves can be used on synthetic webbing, as well as wire rope and chain slings. Check out the chart below to find the best size for you.

| Cordura SKU |

Web SKU |

Sleeve Width (in) |

Web Sling Width (in) |

Round Sling | Wire Rope Dia. (in) |

Chain Size (in) |

||

| 1 & 2 Ply | 3 & 4 Ply | Single Leg | Double Leg | |||||

| CS-3 | WS-3 | 3 | 1 | Types 1 & 2 | 1/4 - 3/4 | 7/32 | ||

| CS-4 | WS-4 | 4 | 2 | 1 | Type 3 | Types 1 & 2 | 7/8 - 1-1/8 | 9/32 - 3/8 |

| CS-5 | WS-5 | 5 | 3 | 2 | Types 4, 5, 6 | Types 3 & 4 | 1-1/4 - 1-1/2 | 1/2 |

| CS-6 | WS-6 | 6 | 4 | 3 | Types 7 & 9 | Types 5 & 6 | 1-5/8 - 1-3/4 | 5/8 |

| CS-8 | WS-8 | 8 | 5 & 6 | 4 & 5 | Types 10 & 11 | Types 7 & 9 | 2 - 2-1/2 | 3/4 - 7/8 |

| CS-10 | WS-10 | 10 | 8 | 6 | Type 12 | Type 10 | 1 | |

| CS-12 | WS-12 | 12 | 10 | 8 | Type 13 | Types 11 & 12 | 1-1/4 | |

| CS-14 | WS-14 | 14 | 12 | 10 | Type 13 | |||

Quick Sleeves

Quick sleeves come with Velcro® for quick installation and removal. This style is excellent for operations where this kind of flexibility is required.

Quick Sleeve Sling Compatibility

The below chart can help you find the best quick sleeve width for your application.

| Cordura SKU |

Web SKU |

Sleeve Width (in) |

Web Sling & Width (in) |

Round Sling | Wire Rope Dia. (in) |

Chain Size (in) |

Velcro® (in) |

||||

| 1 & 2 Ply | 3 & 4 Ply | Single Leg | Double Leg | 1-2 Ply Single Leg | 3-4 Ply Double Leg | ||||||

| CQS-3 | WQS-3 | 3 | 1 | 1/4 - 7/16 | 1 | 1 | |||||

| CQS-4 | WQS-4 | 4 | 2 | 1 | Types 1, 2, 3 | Type 1 | 1/2 - 3/4 | 7/32 - 9/32 | 1 | 1 | |

| CQS-5 | WQS-5 | 5 | 3 | 2 | Types 4 & 5 | Types 2 & 3 | 7/8 - 1-1/8 | 3/8 | 1 | 2 | |

| CQS-6 | WQS-6 | 6 | 4 | 3 | Types 6 & 7 | Types 4 & 5 | 1-1/4 - 1-1/2 | 1/2 | 1 | 2 | |

| CQS-8 | WQS-8 | 8 | 5 | 4 | Types 9 & 10 | Types 6 & 7 | 1-5/8 - 2-1/4 | 5/8 | 2 | 2 | |

| CQS-10 | WQS-10 | 10 | 6 |

5 & 6 | Types 11 & 12 | Types 9 & 10 | 1-1/2 | 3/4 - 7/8 | 2 | 2 | |

| CQS-12 | WQS-12 | 12 | 8 |

8 | Type 13 | Type 11 | 1 | 2 | 2 | ||

| CQS-14 | WQS-14 | 14 | 10 |

10 | Type 12 | 2 | 2 | ||||

| CQS-16 | WQS-16 | 16 | 12 | 12 |

Type 13 | 2 | 2 | ||||

Tubular Sleeves

Tubular sleeves also have Velcro®, and are designed to maximize their usable surface area. This generally means they will last longer than the other styles if you adjust the contact points on each load.

Tubular Sleeve Sling Compatibility

This style is compatible with round slings, wire rope, and chain slings. Learn more in the chart below.

| Cordura SKU |

Web SKU |

Sleeve Width (in) |

Round Sling | Wire Rope Dia. (in) |

Chain Size (in) |

|

| Single Leg | Double Leg | |||||

| CQTS-6 | WQTS-6 | 6 |

1 - 1-1/2 |

9/32 - 3/8 |

||

| CQTS-8 | WQTS-8 | 8 |

Types 1 & 2 | 1-3/4 - 2 | 1/2 - 5/8 | |

| CQTS-10 | WQTS-10 | 10 |

Types 3, 4, 5 | Types 1, 2, 3 | 2-1/4 - 2-1/2 | 3/4 |

| CQTS-12 | WQTS-12 | 12 |

Types 6 & 7 | Types 4, 5, 6 | 7/8 - 1 | |

| CQTS-14 | WQTS-14 | 14 |

Type 9 | Type 7 | 1 - 1-1/4 | |

| CQTS-16 | WQTS-16 | 16 |

Type 10 | Type 9 | ||

| CQTS-18 | WQTS-18 | 18 |

Types 11 & 12 | Type 10 | ||

| CQTS-20 | WQTS-20 | 20 |

Type 13 | Type 11 | ||

| CQTS-22 | WQTS-22 | 22 |

Type 12 | |||

Sling Protector Inspections

All sleeves need to be inspected periodically, including before each use.

If you find any damage, you should remove the sling from use immediately. Some commonly-found issues including abrasion damage, tears or cuts in the fabric, chemical or temperature damage, and illegible warning tags.

USCC: Your Lifting Sling Resource

We offer a wide range of lifting slings, including nylon, polyester, plasma, as well as other sling protection options. You will also find a full selection of rigging hardware.

Questions? Call to speak to one of our product specialists today!